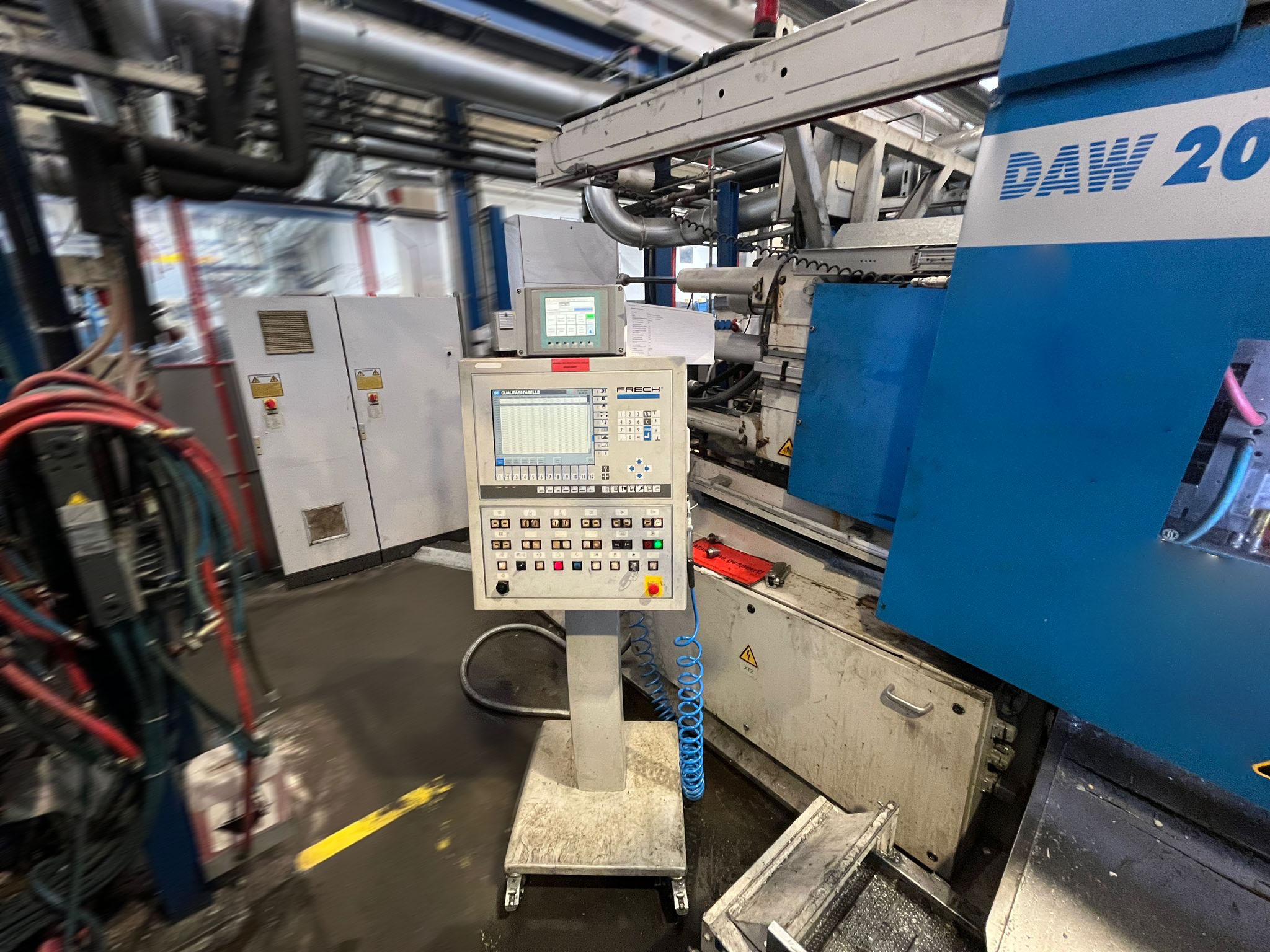

Producing zinc-, magnesium-, tin- and lead-parts in large quantities is the specialty of hot chamber die casting machines. When it comes to producing largely finished moulded products made of various metals, a hot chamber die casting machine is often the best choice. Only zinc, tin, lead and magnesium alloys are possible materials for the hot chamber die casting process. Good flow-properties and a low melting-point of the used materials are crucial to this process.

High pressures and temperatures – convincing clock-rates

Typical operators of hot chamber die casting machines are manufacturers of furniture- and construction-fittings, components for the automotive-, electrical-tools- and electronics-industries or toys.

A dividable mould is hydraulically held together with a closing-force up to 50.000 kN, while it is filled with liquid metal at a specific moulding-pressure of up to 400 daN/cm². Via a sprueing channel the molten metal enters a separable permanent-mould. This forms cavities in the closed state in which the liquid melt is injected under high pressure. After the metal has solidified in the mould, the mould-halves are separated and the product is removed. Large or sensitive components are released with a foundry robot from the mould. Subsequently, the product is released from excess-material with a trimming press and optionally further reworked.

The name "hot chamber die casting machine" comes from the fact that the sprue-bushing of the die casting mould is in constant contact with the melt. Cycle-times with an average of 10 seconds per shot are possible with this process. For best results, the die casting moulds are often run with tempering-devices. Consistent quality with millions of quantities is one of the outstanding features of hot chamber die casting machines.

Hot chamber die casting machines – valuable used machines

Hot chamber die casting machines are special machines. Since the components remain operational away with proper use and maintenance over many years, they are very interesting for the second-hand-market. To ensure as many operating hours, all aggregates on the die casting machines need to be of the highest quality.

This very fact makes them valuable as used systems foundry-machines.

Fiss-Machines offers you know-how and experience

We, at Fiss, deal with used hot chamber die casting machines for more 30 years and have been able to pass on hundreds of used systems and successfully install them on a new site.

Our adeptness and high expertise distinguishes us just as much as the distribution of suitable peripheral-machines and automation-technology.

With us you can rely on s full-service. We inform you about a necessary part- or complete-revision of your favourite system, as well as about appropriate automation-facilities and other service-offerings. We advise you intensively and continuously with the purchase or sale of your used hot chamber die casting machine.

Our prices are based on the market-orientation as well as on the additional-automation and services you have selected. We will gladly take care of the entire process of evaluating the used system, dismantling, logistics and transportation, as well as the commissioning and briefing at the new location.