Filter products

- Used Machines

- News

- Search Machines

- Your Offer

- Accessories

- Service

- Events

- About us

- Contact

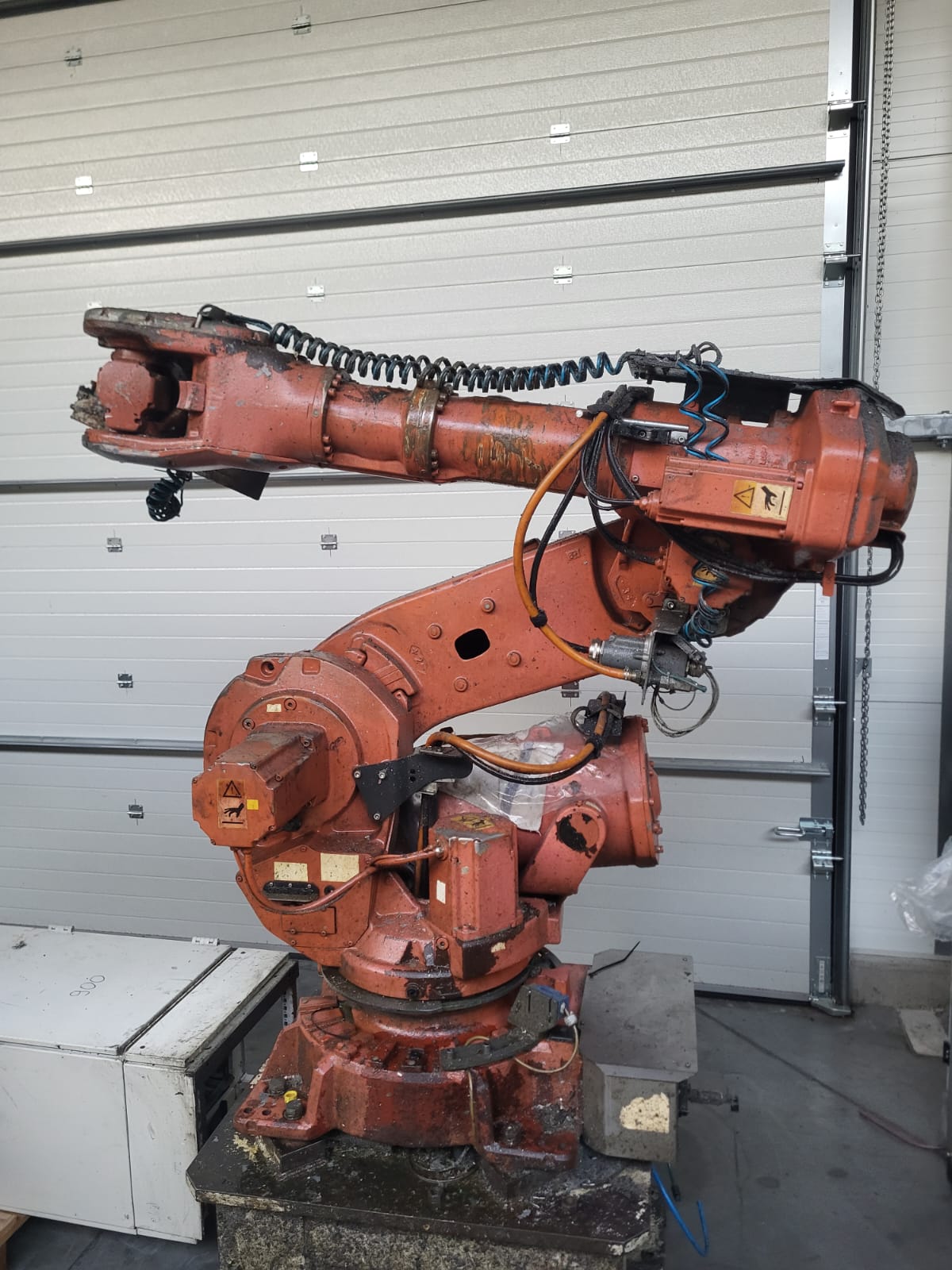

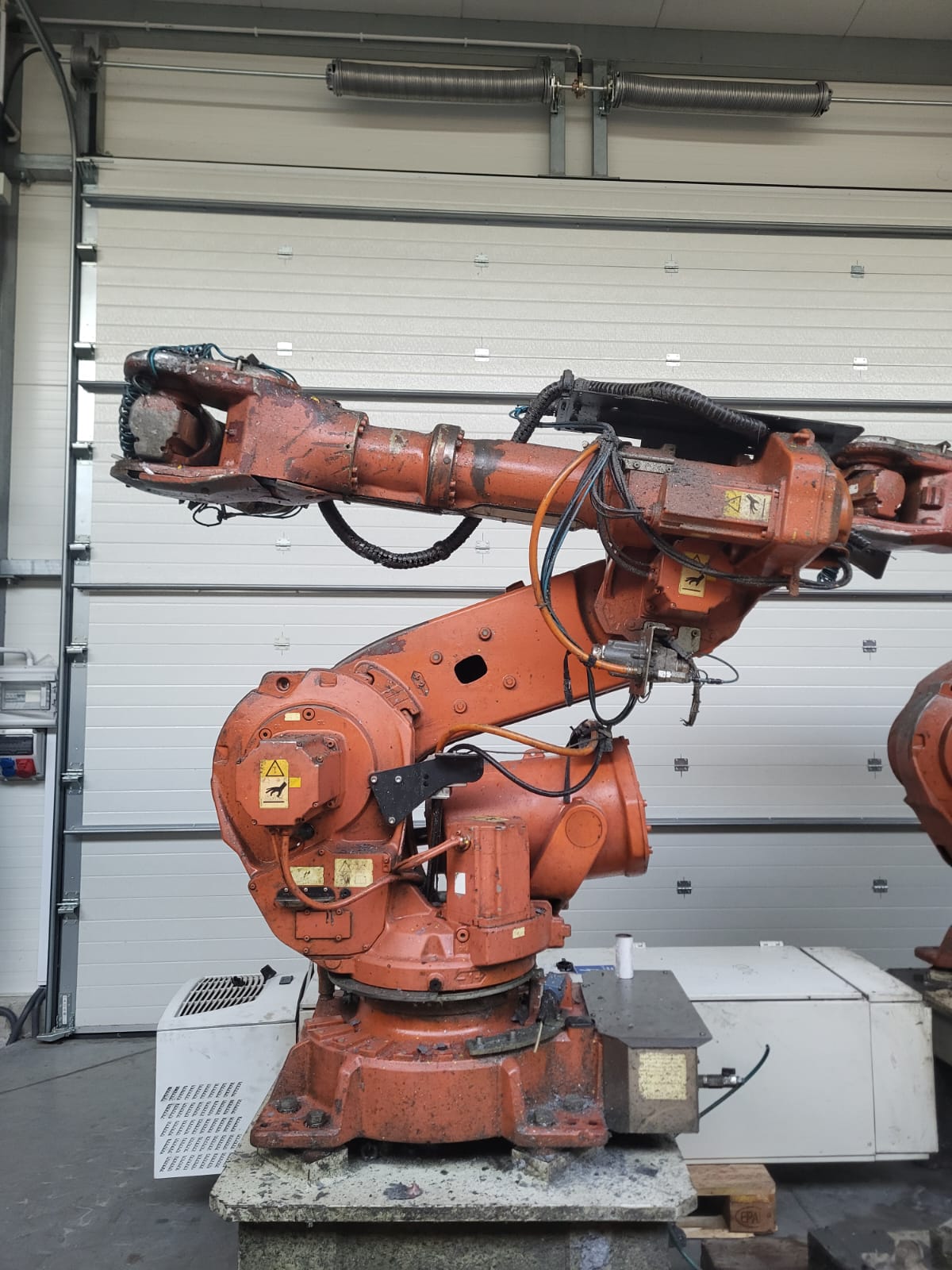

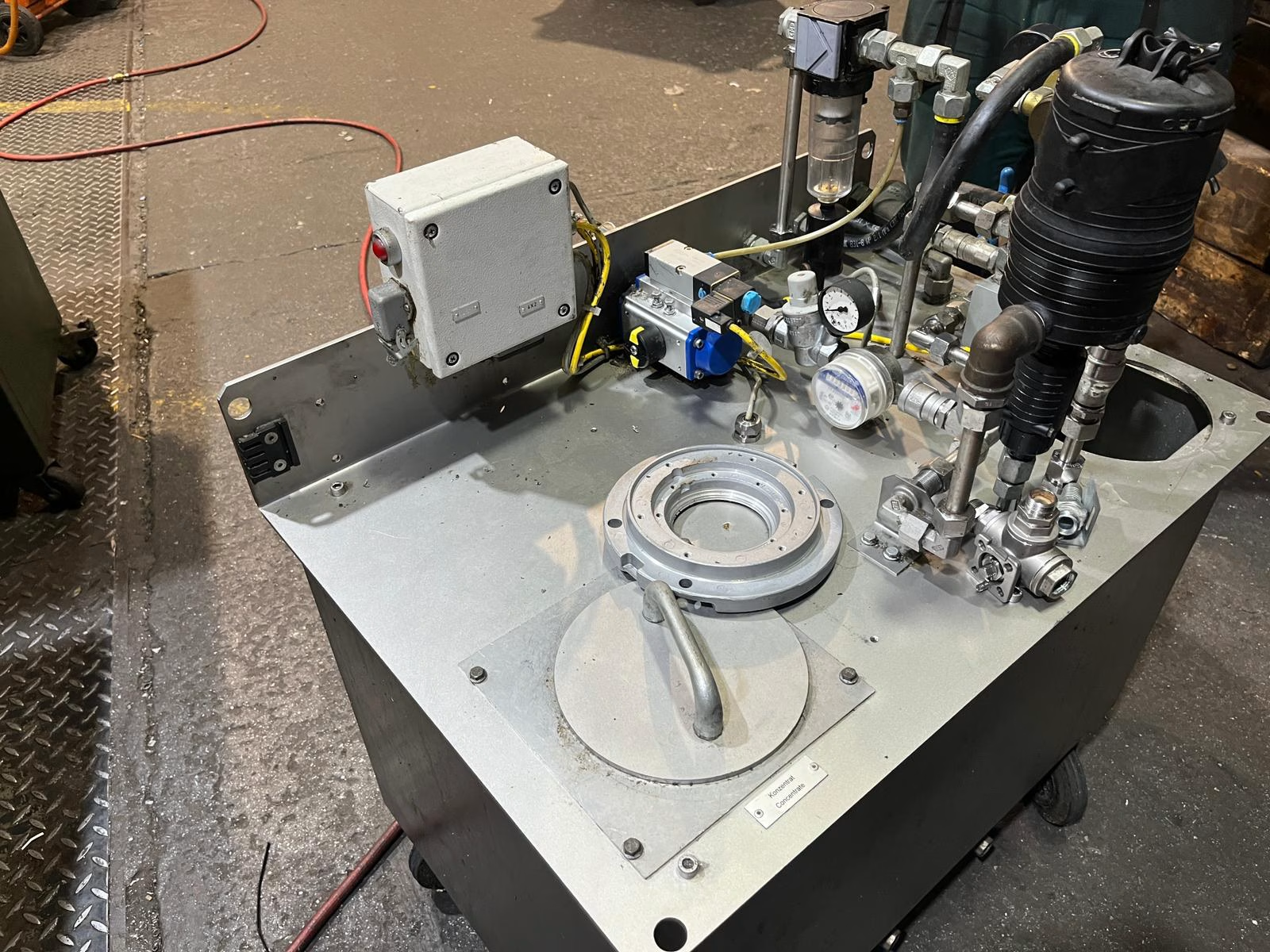

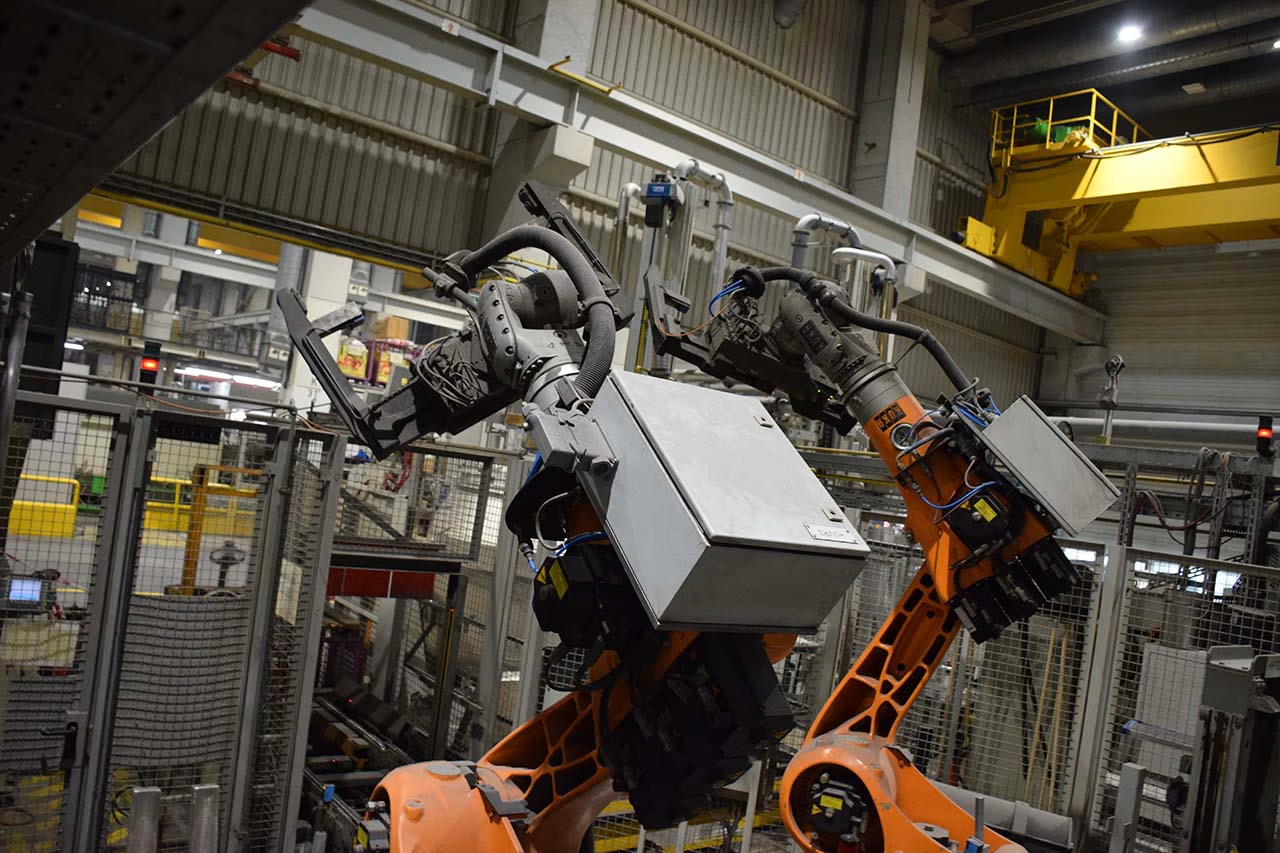

We offer used equipment and devices for automation in cold chamber die casting: metal dosing furnaces or metal dosing units, piston lubrication devices, mould heating and cooling devices, motorized mould spraying machines or spraying robots, foundry robots or casting removal devices, control and marking devices, water cooling basins or air blowers and trimming presses. Among them you will find manufacturers such as KUKA, ABB, FANUC, Kawasaki, Acheson, Wollin, Gerlieva, Böhmer, Spesima, Bühler, Tecnopresse, Reis, Diesse, Robopress, Gerlieva and others.

The processes in cold chamber die casting are ideally suited for a fully automatic configuration. There is a large number of devices and equipment around the cold chamber die casting machine that allow it to be expanded to a fully automated casting cell. For example, dosing furnaces, mould spraying machines, removal robots and trimming presses can be installed to form automatically operating casting cells. Automation in cold chamber die casting shows its great efficiency when it comes to the production of high volumes and short cycle times.

The advantages of automation in cold chamber die casting

- Continuous production without manual intervention

- High process reliability

- Fast production of high volumes

- High quality castings

- Increase of profitability

- Full and partial automation is possible

- Lower error rate = less scrap

Robots in the automated foundry of KUKA and ABB

Today, robots are an important component in automation in cold chamber die casting. Whether filigree castings or heavy components - robots in the foundry carry out all the steps assigned to them in automated processes precisely, reliably and quickly. They are equipped with special seals and are optimally protected against the harsh environment, spray vapors, heat and corrosion. Thanks to their robust design, the grippers of foundry robots are optimally equipped for use in critical foundry conditions. They can thus safely do their job around the clock in automated foundries - even under the most extreme conditions. They provide the decisive advantage of dynamics, flexibility and cost-effectiveness in automation in cold chamber die casting.

We are your experts for automation in cold chamber die casting

Whether you are interested in individual peripheral devices for the automation of your cold-chamber die casting system or are looking for complete automation equipment, it makes no difference. We are the experts with the comprehensive knowledge of the industry and are happy to advise you on the purchase and sale of new or used machines for automation in the foundry.

To ensure that cold chamber die casting machines operate reliably and economically, the quality of the peripheral equipment is of great importance. After a partial or complete overhaul, our machines and equipment are ready to support the automation of your cold chamber die casting system.

Trust in our over 30 years of experience and unique expertise in the casting industry. In addition to highly qualified engineers and technicians, we offer you a comprehensive all-round service, ranging from dismantling and overhauling the machine to taking over transport, commissioning and instruction at the new location.

Let us convince you of our individual offers and trust in the experts of Fiss Machines!