-

Professional overhaul

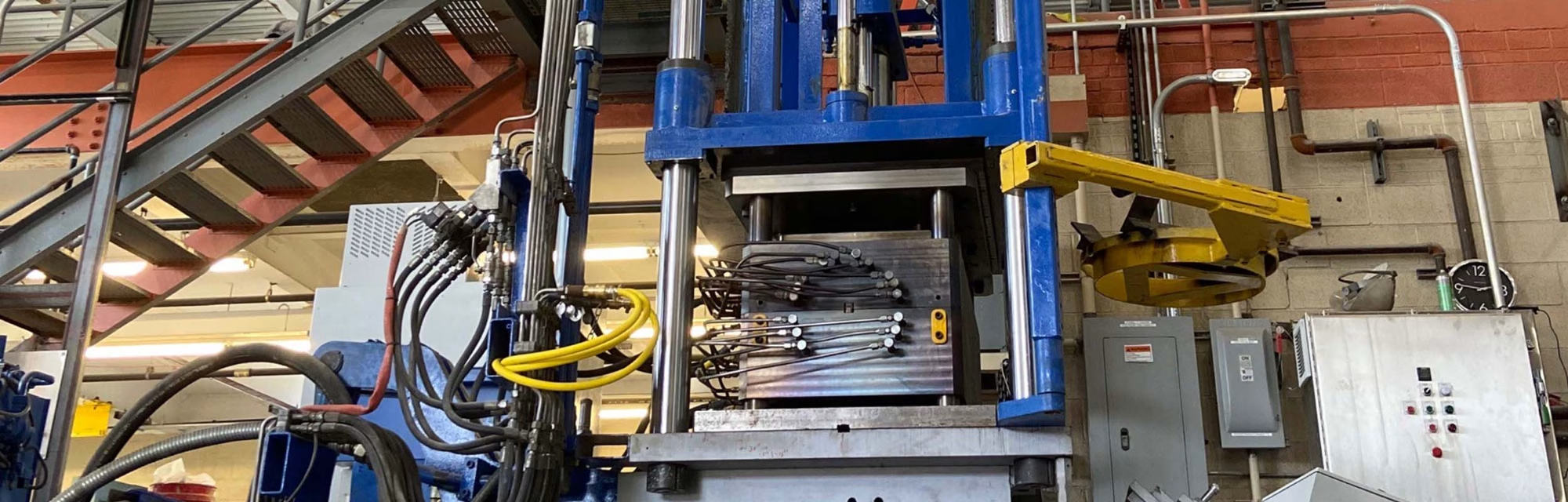

Expert overhaul, repair, modernisation and functional testing of die casting machines, furnaces, equipment and more

Details -

Professional overhaul

For the overhaul of equipment for the foundry industry, we offer various and staggered scopes of services such as functional testing, repair, partial overhaul and general overhaul.

Details -

Professional overhaul

With our machine overhaul, you ensure the continuous productivity of your foundry machines and avoid costly downtimes. Better not drive for wear and tear, but act in good time and with foresight.

Details -

Professional overhaul

According to the scope of your order, we reliably dedicate ourselves to all necessary work steps. If you wish, we can also develop and implement solutions tailored specifically to your needs.

Details -

Professional overhaul

With every order for the overhaul of your die casting system, you can look forward to a smooth, personal and transparent cooperation with us.

Details

Filter products

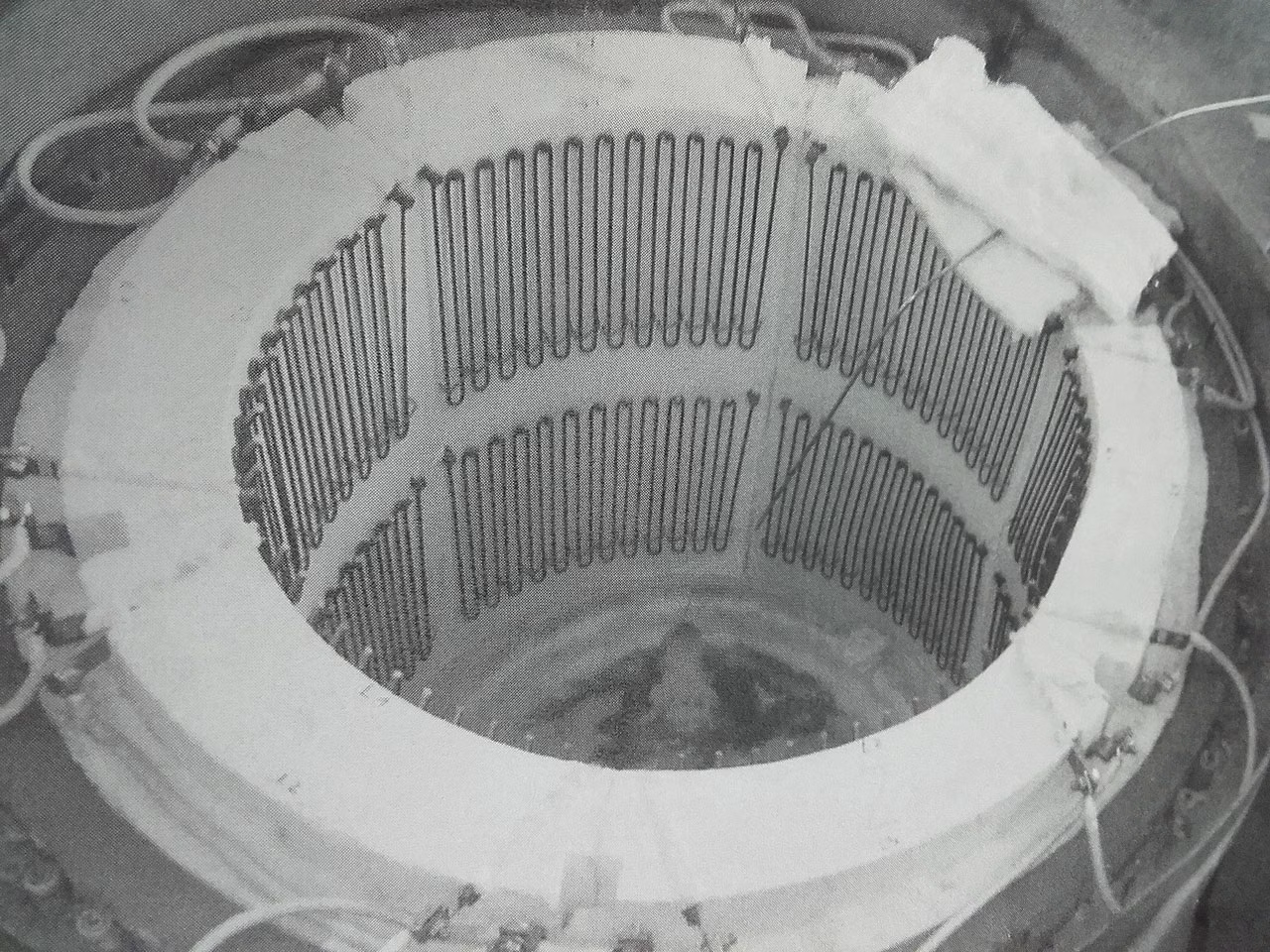

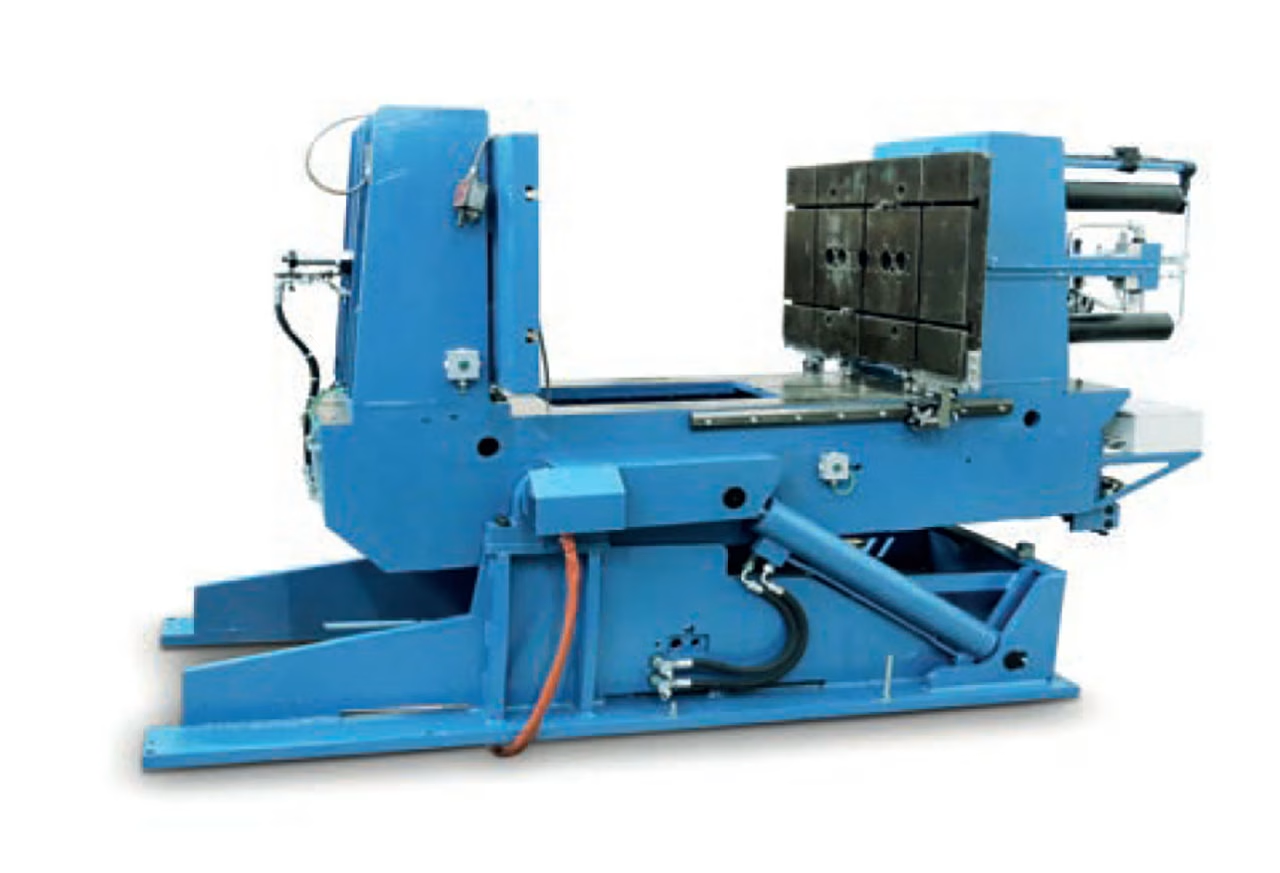

For the overhaul of plants for the foundry industry, we offer you different and staggered scopes of services such as functional testing, repair, partial overhaul and general overhaul. According to the scope of your order, we reliably take care of all the necessary work steps. On request, we can also develop and implement solutions tailored to your specific needs.

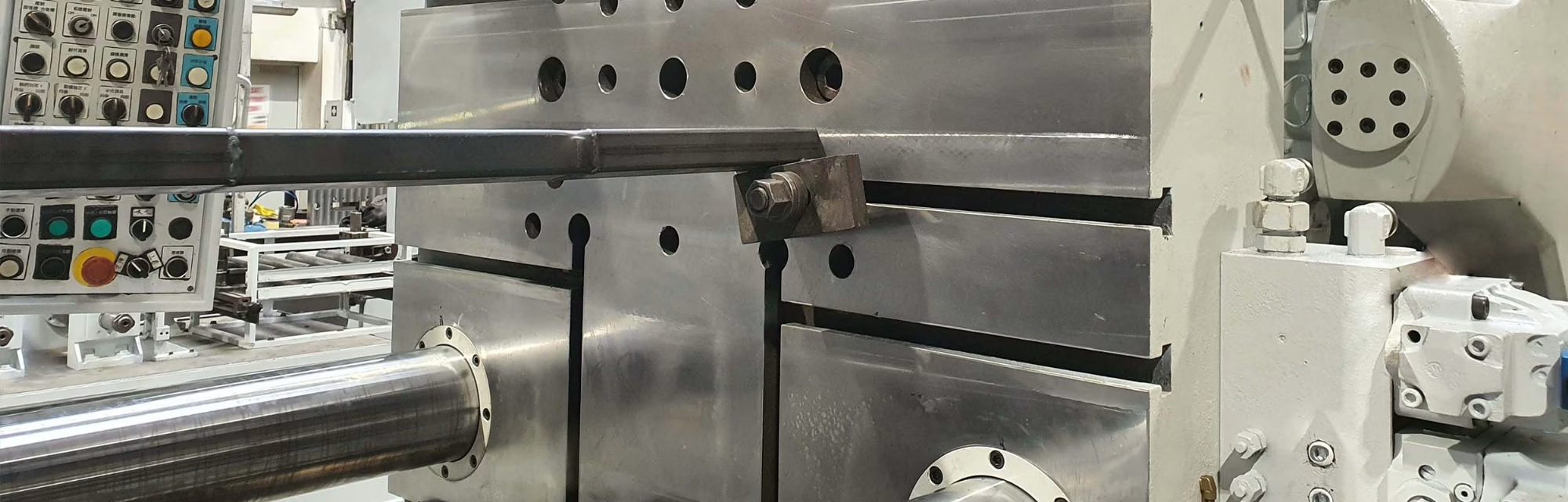

Your die casting equipment is getting on in years and could do with a freshening up by an expert? With our machine overhaul, you can ensure the continued productivity of your foundry machines and avoid costly downtime. Better not drive on wear and tear, but act in good time and with foresight.

Our scope of services for machine overhaul in detail for the areas of functional testing, clamping part overhaul, partial overhaul and general overhaul:

Why should you decide for an overhaul of used plant and machinery for the foundry industry by fiss machines?

- Up to 50 % less costs compared to a new acquisition

- Higher system availability

- Upgrading to the latest technology, modernisation

- Components from renowned manufacturers

- Functional expansion, modifications

- Process optimisation through automation equipment

Proven competence and full service in plant overhaul

Our experienced team accompanies you through all projects from order acceptance to recommissioning. With every order for the overhaul of your die casting machines, you can look forward to a smooth, personal and transparent cooperation with us. We will keep you regularly informed about the progress of the project. Together with you, we will optimise the availability and service life of your foundry machinery.