Filter products

- Used Machines

- News

- Search Machines

- Your Offer

- Accessories

- Service

- Events

- About us

- Contact

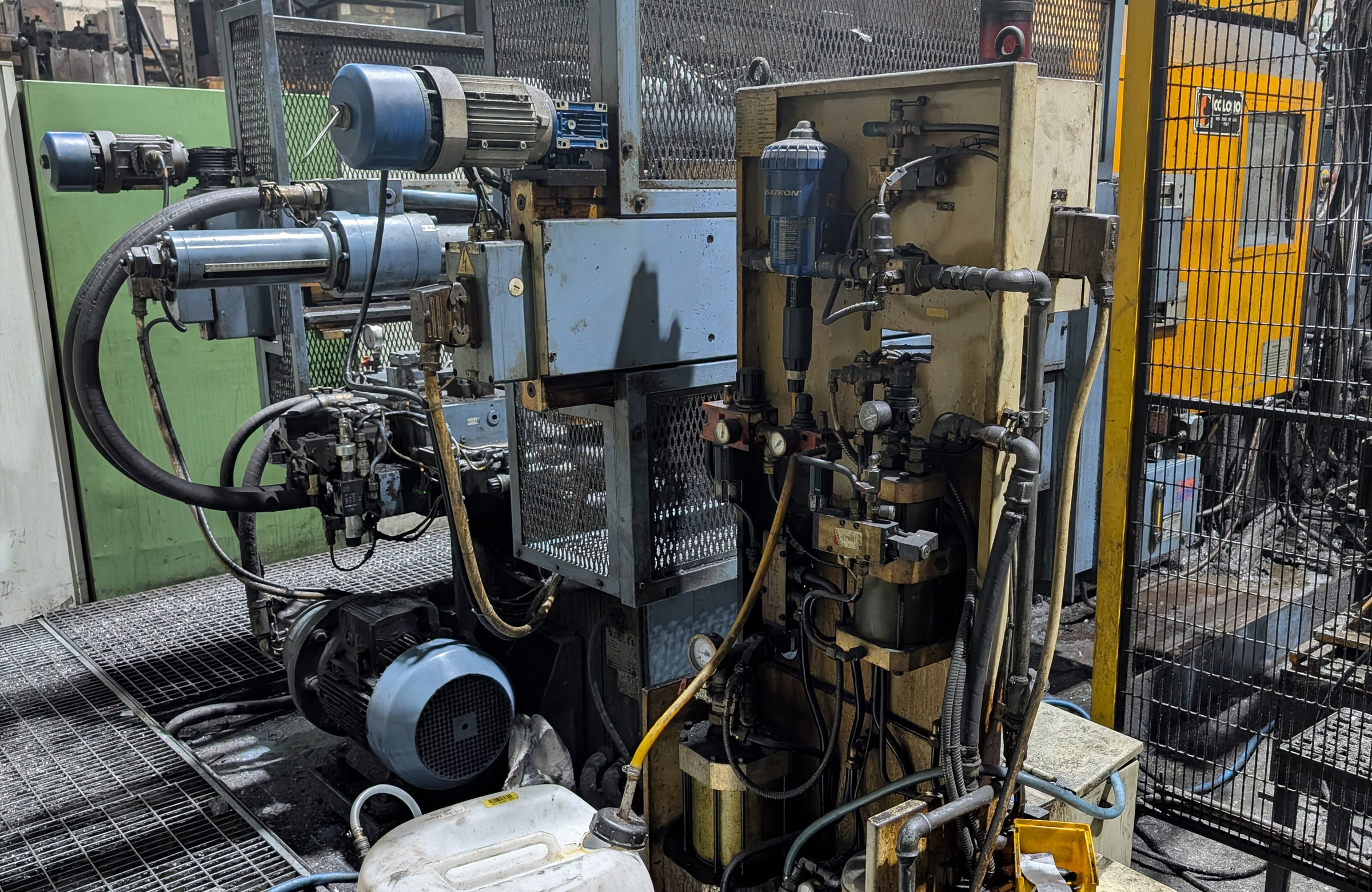

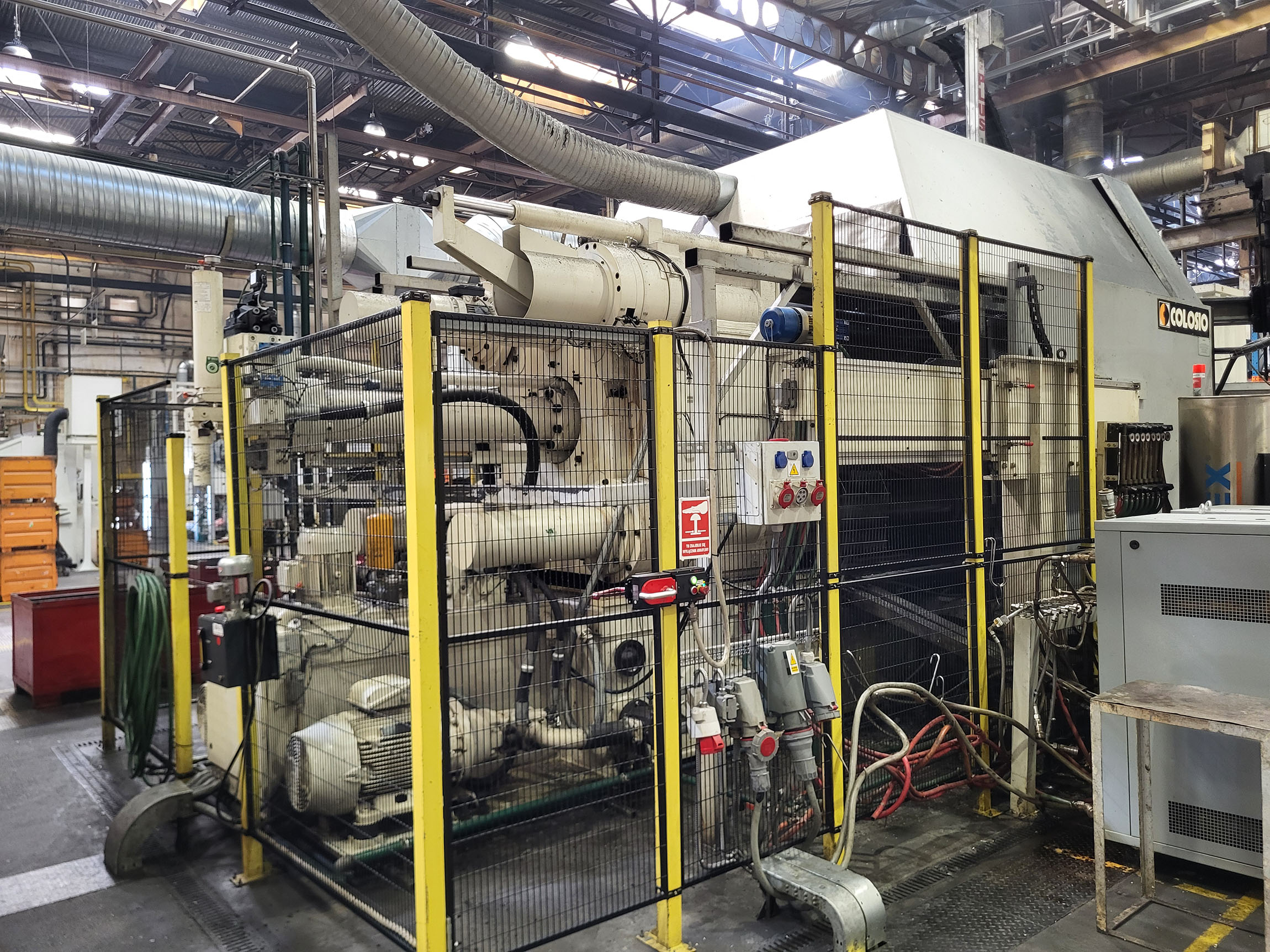

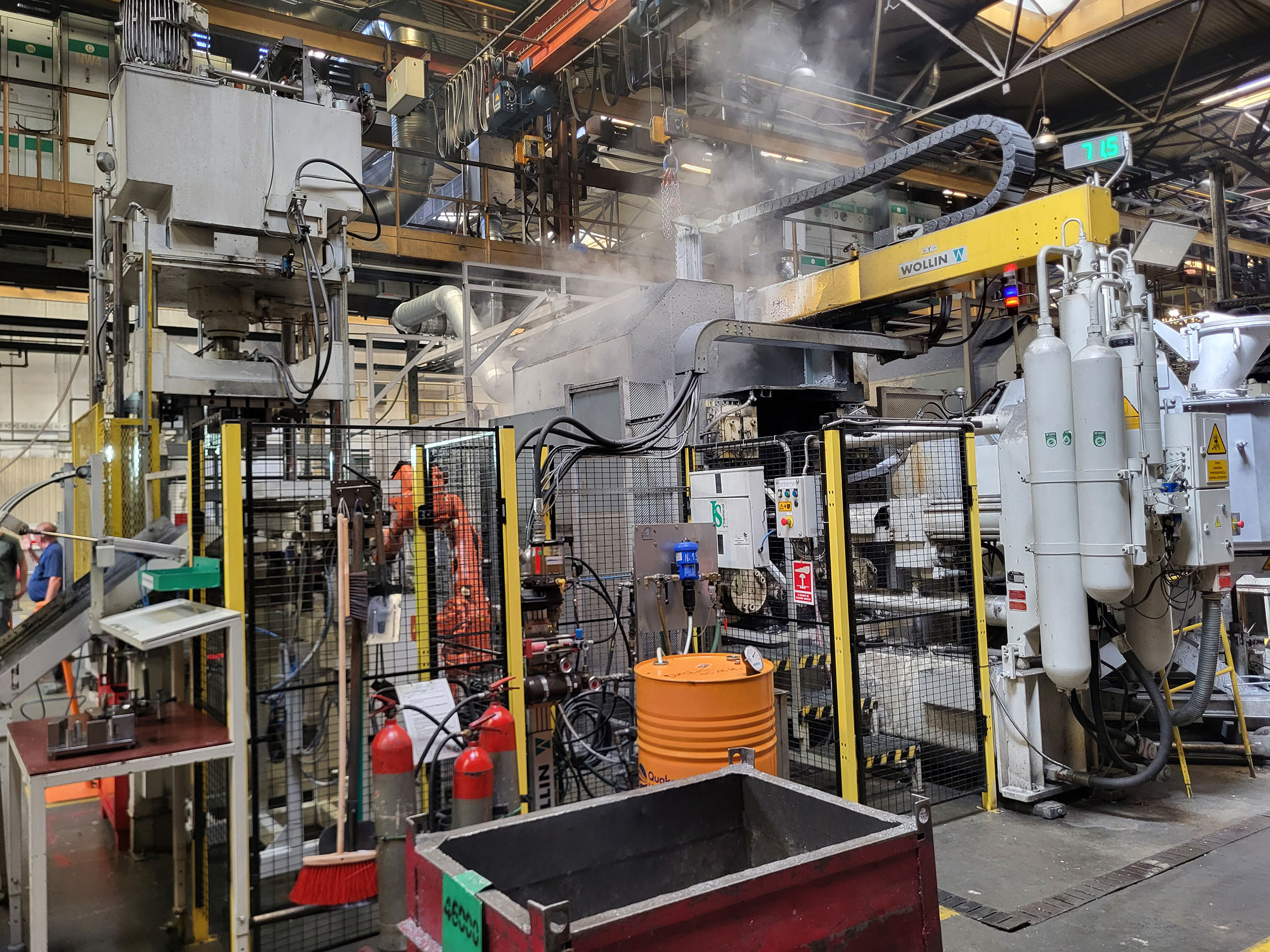

Die casting machines are used to press liquid metallic raw material with a low melting point into a complex form. Because of short production cycles and achievable component properties, die casting machines are used in a wide field of application, like automotive industry or mechanical engineering.

In the industrial scale zinc-, magnesium- and aluminum alloys are used predominantly, but there has to be made a distinction between the different machines, which work either with the hot chamber or the cold chamber method. The constructive difference lies in spatial separation of the injection- and press system of furnaces.

Hot chamber die casting machines by Frech, Colosio or Agrati

In the hot chamber procedure there are used mainly zinc-, tin-, plumb- and magnesium alloys with a melting point which is lower than 630°C. This allows that the injection system and the furnace form a unity when the gooseneck is dipped into the melt. Because of the vertical injection system the melt flows automatically into the casting tank during the piston stroke. Via the mouthpiece body the liquid metal is going to be pressed into the form. This special construction for forming leads to very short cycle times and very low unit prices.

Cold chamber die casting machines by Italpresse, Bühler, Frech, Weingarten or IDRA

The cold chamber procedure is mainly used for aluminum- and magnesium alloys with a melting point higher than 630°C. This high melting temperature and the components of the aluminum alloys only allow processing in the cold chamber procedure. The furnace and the injection system are separated. The melt is led manual or via the metal loader into the press chamber from where it is pressed horizontal or vertical into the casting mould. A new filling of the press chamber can only take place after the solidified element is removed.

Automation mechanism

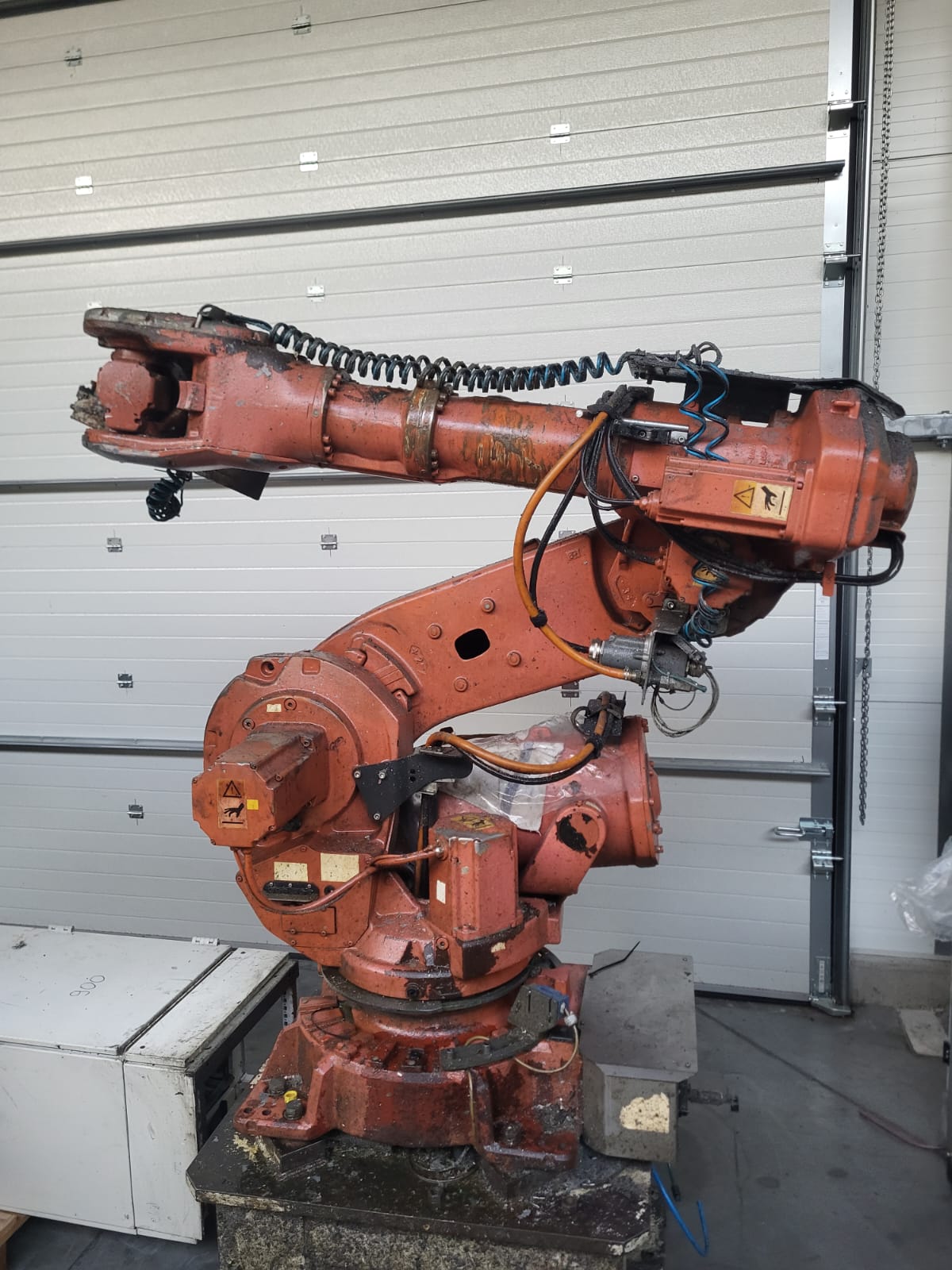

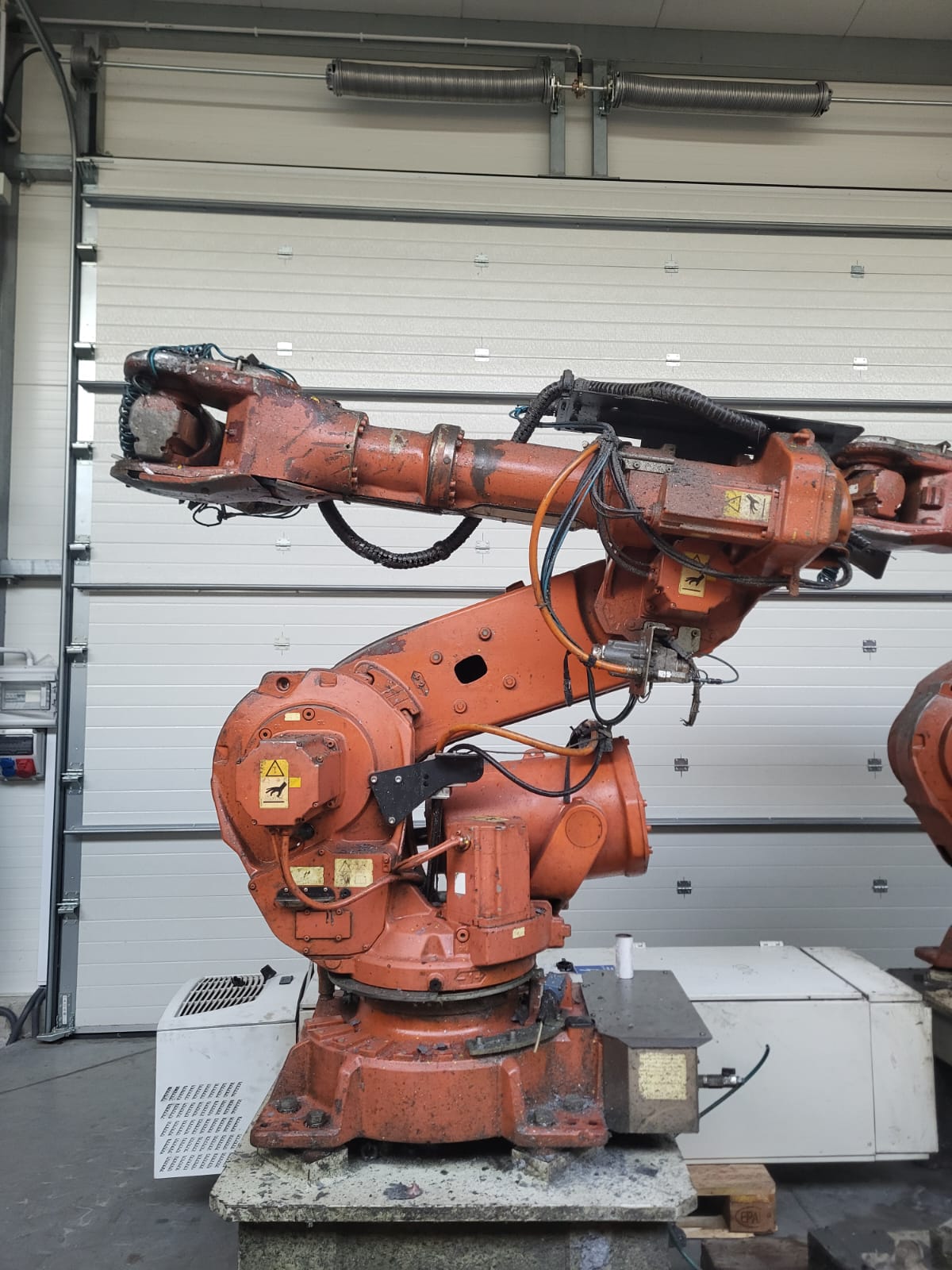

You search for automation for your die casting machine? We offer new and used automation mechanisms, peripheral devices and relevant die casting equipment. Whether injection moulding systems, metal loaders, foundry robots or dosers – besides hot chamber and cold chamber die casting machines, we offer numerous used and new band-conveyors, weight sensing devices or separation drums.

You can use our query for special questions about a certain automation mechanism or other accessories.

Full service at Fiss-machines

Fiss offers used hot chamber die casting machines as well as cold chamber die casting machines. Benefit from more than 30 years of know-how in the field of die casting technology – we support your search for a suitable machine. You get an individual offer which is tailored to your demand. In addition to selling machines, this can comprise revision of the machine or certain devices. With our longtime partners we offer extensive logistics-, montage- and implementing services for a successful integration of the machine into your production process.