-

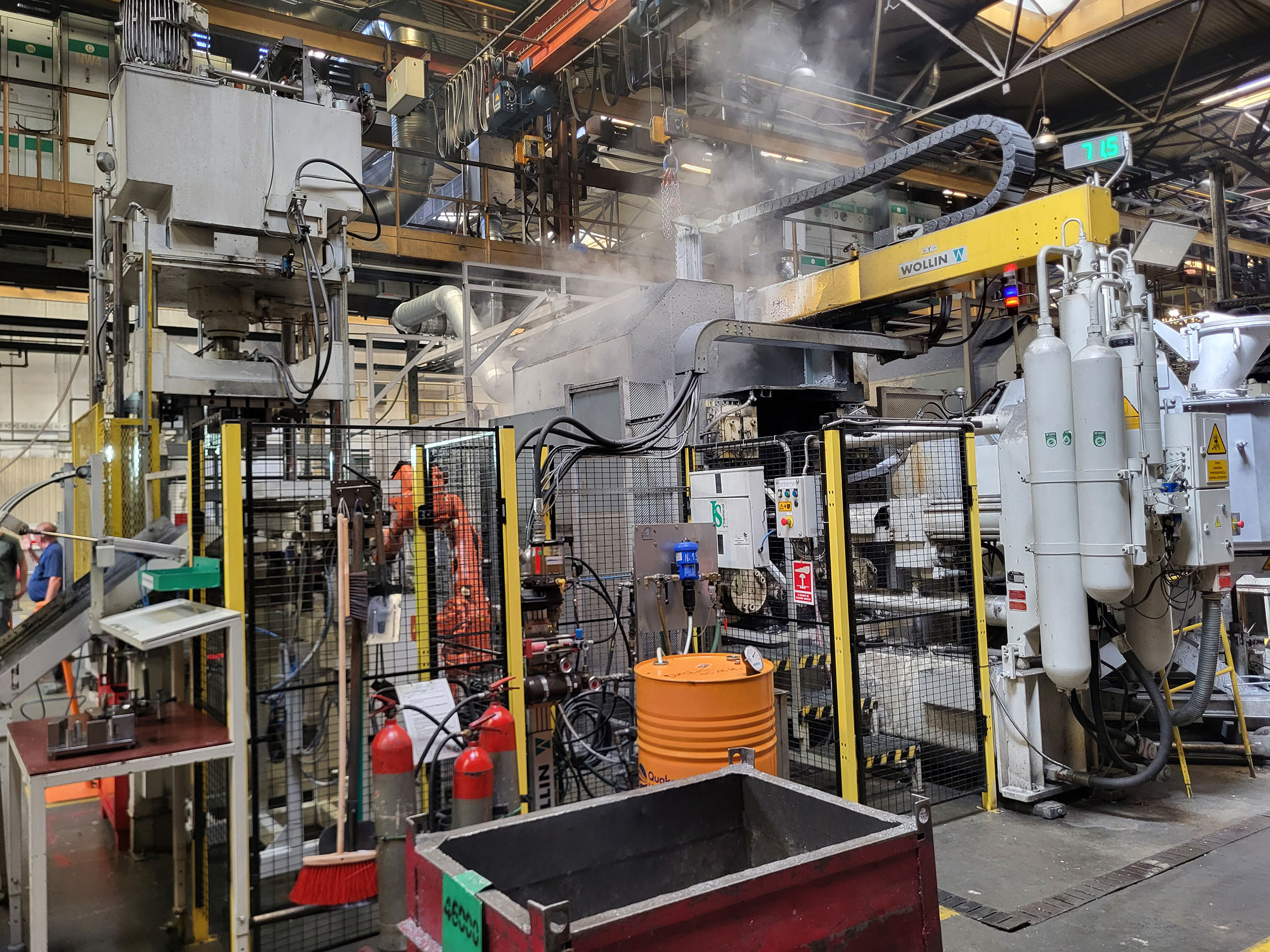

Hot Chamber Die Casting Machines

Producing zinc-, magnesium-, tin- and lead-parts in large quantities is the specialty of hot chamber die casting machines.

Details -

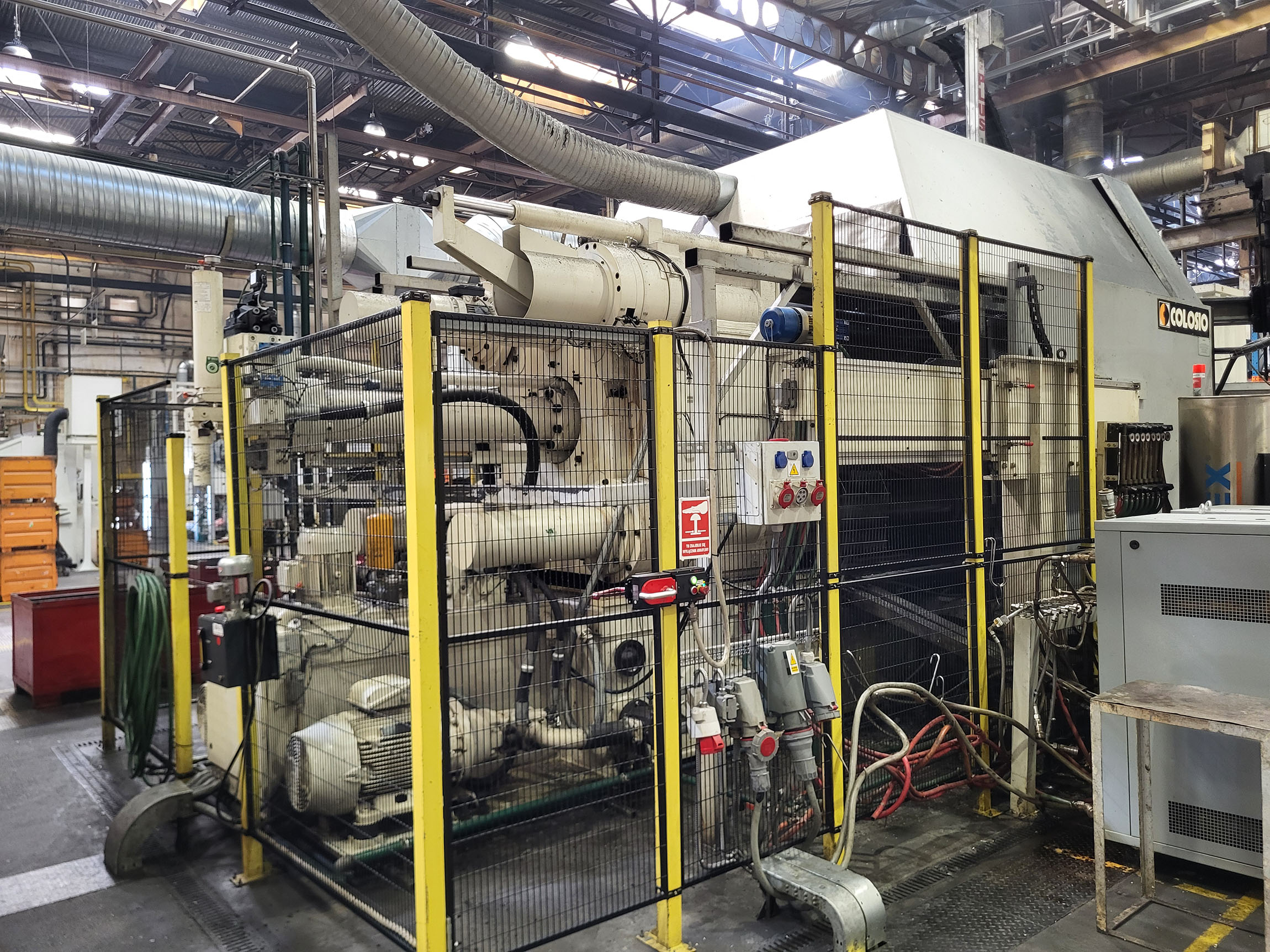

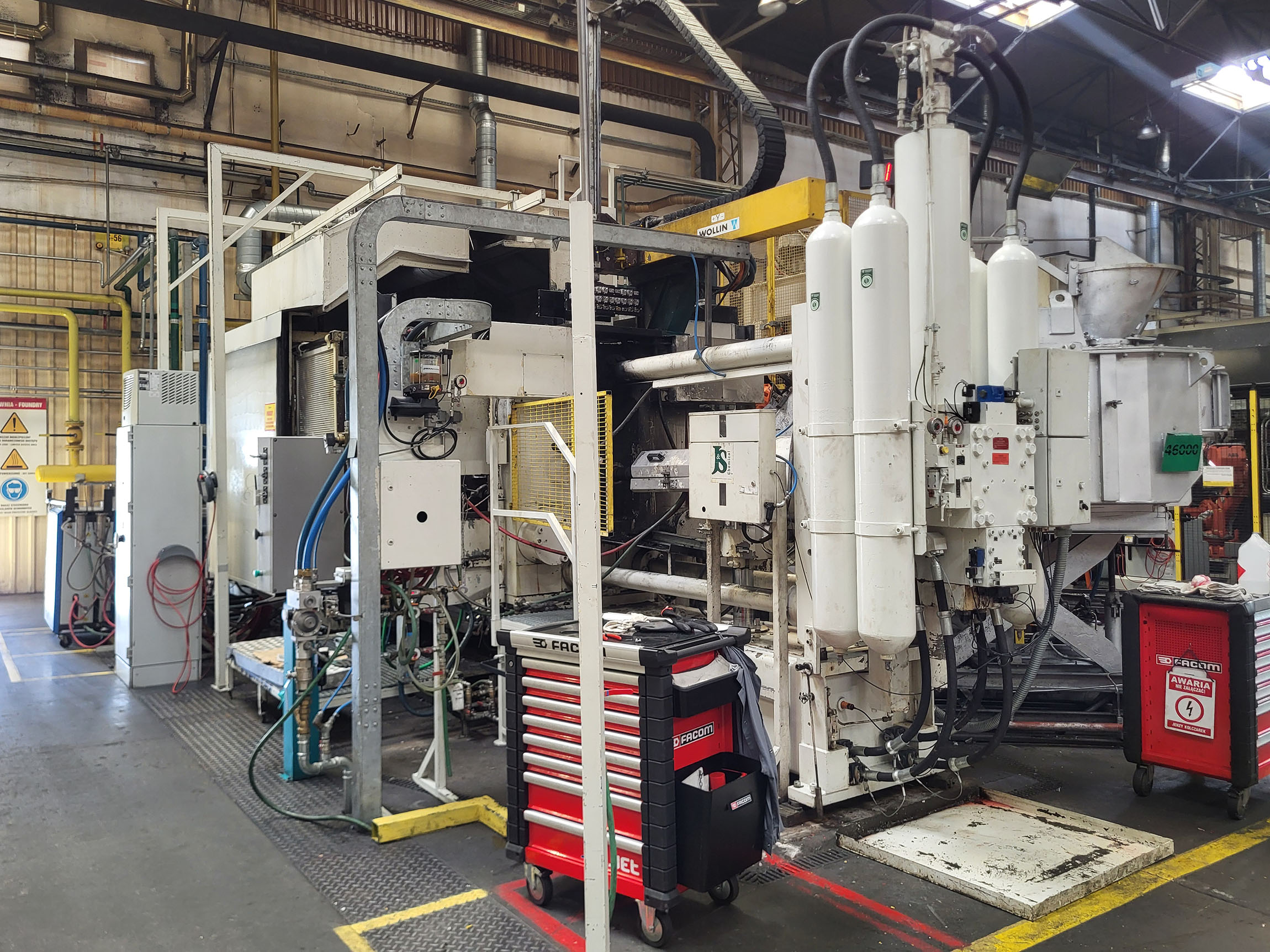

Cold Chamber Die Casting Machines

The special feature of the cold chamber manufacturing process is that the melting- and holding-process is separated from the manufacturing production process.

Details -

Low Pressure Die Casting Machines

from well-known manufacturer as Kurtz, CPC, GIMA, LPM and Borli.

Details -

Used Furnaces For Foundries

from well-known manufacturer as Striko Westofen, ZPF, Hindenlang, Rauch, Meltec, Nabertherm, STOTEK for melting of Aluminium, Magnesium, Brass and Zinc alloys.

Details -

Used Aluminium Gravity Casting Machines

Here you will find used gravity die casting machines, gravity casting machines and tilting casting machines for the processing of aluminium and brass alloys from established manufacturers such as Kurtz, FILL, LPM, Gauss, IMR and Vihorlat.

Details -

Used core shooters

Here you will find used core shooters from Laempe, Loramenti and Hottinger for all common core making processes such as cold and hot box, CO2 process and croning process

Details -

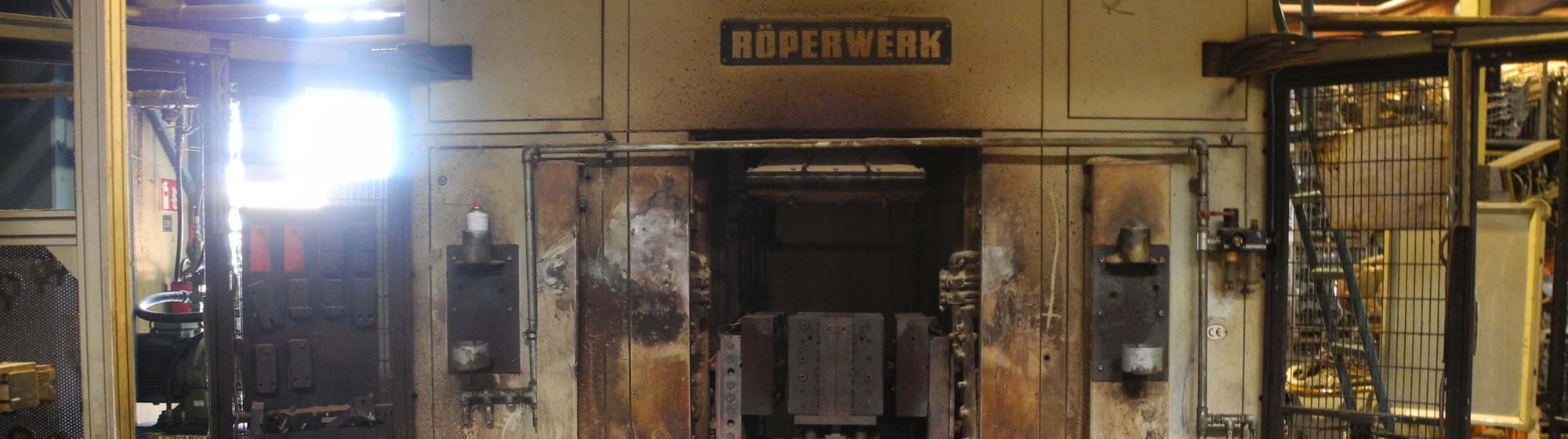

Used presses

We offer used mechanical and hydraulic presses as transfer presses, line of presses, crank presses, eccentric presses, hydraulic presses, punching machines, stamping presses, blanking and forming presses, spotting presses, forging presses for steel and brass, toggle presses

Details

Filter products

We, at Fiss, are one of the leaders in buying, selling and mediating of used die casting machines. We have specialized in the distribution of used die casting machines of renowned manufacturers on the market. Benefit of our competent know-how and over 30 years of experience in the successful distribution of foundry machines and related peripherals devices.

In many cases, the purchase of used foundry machines represents an economically attractive alternative to purchasing new systems.

We offer used machines in a very good price-performance-ratio, which are still reviewed on the fly by us in most cases. Your benefit is a real assessment of the state of the system under production conditions. Many photos and a detailed description of the used machines by our professional staff confirm this impression.

In the case of a partial or a complete overhaul of the selected machine we make you an individual offer. Insofar as it does not exist already, you can also request appropriate automation equipment and accessories for the selected system.

We offer you a comprehensive all-round-service, which for example includes the dismantling of the used system up to the handover in an operative state in your company.

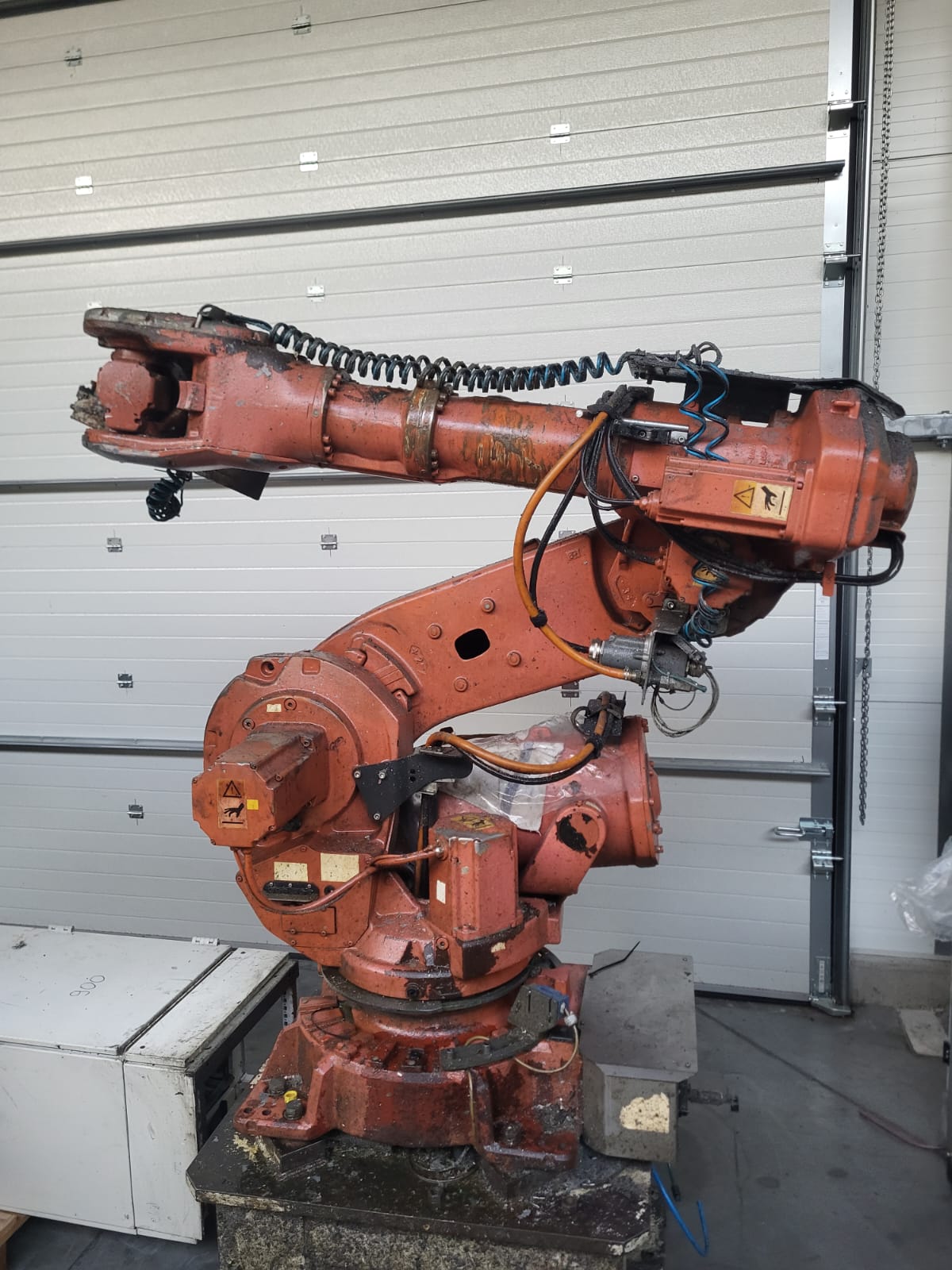

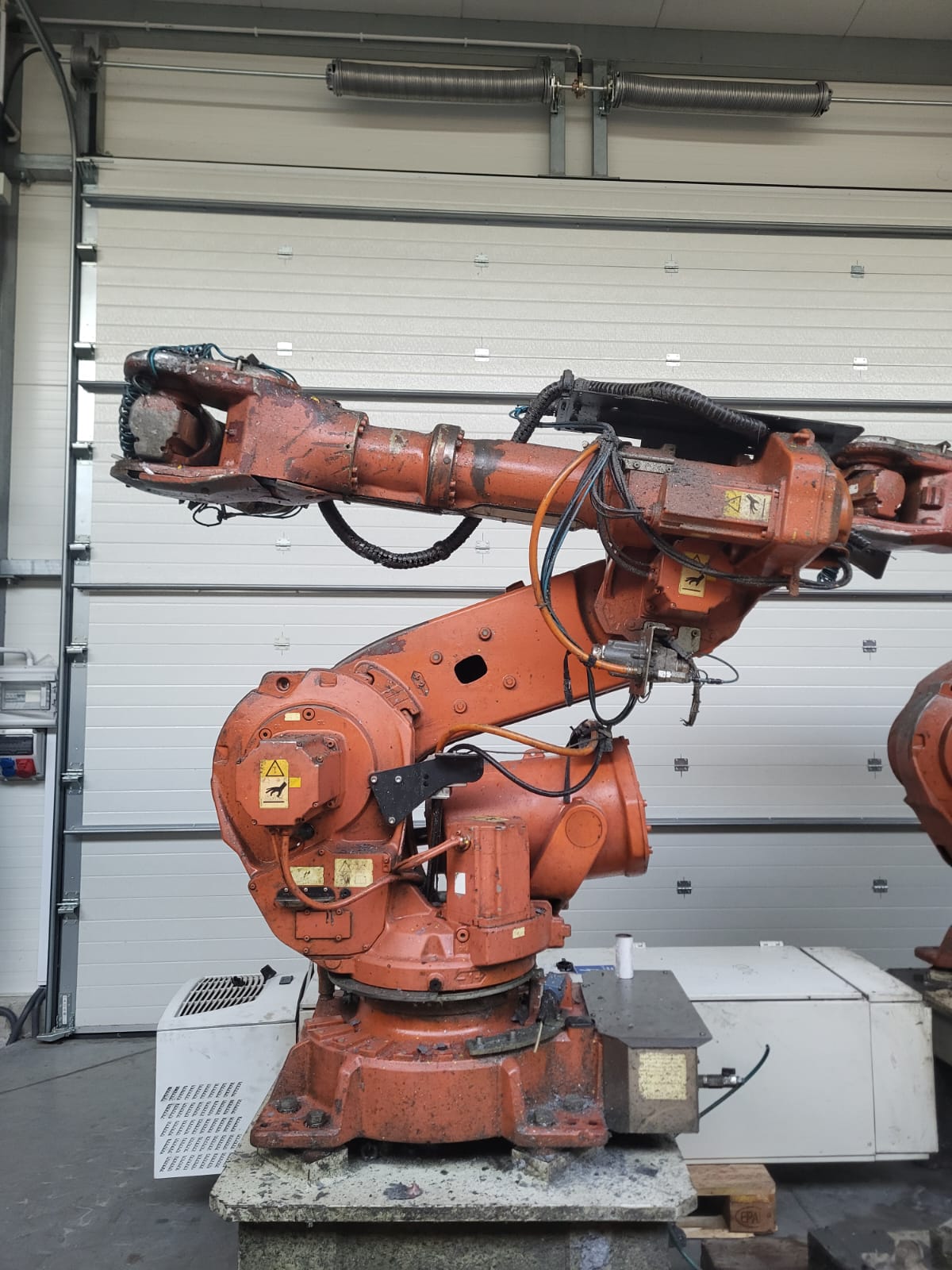

Die casting machines

We offer hot and cold chamber die casting machines for the production of components made of metal with a low melting point. In this case the melt is pressed into the mould under high pressure and with faster flow rates.

The choice between hot chamber and cold chamber die casting machines is based on the actual melting point of the material.

Because our core competence lies in this area, we provide not only used machines, but also the retrofitting of automation equipment and foundry equipment according to the state of the art.

Gravity casting machines

Here you will find used gravity casting machines and low pressure die casting machines, in which the melt due to the gravity or at reduced pressure application enters the mould. We also offer appropriate accessories and modern machine controllers for the gravity casting machines as well.

Extrusion machines

We mediate used extrusion presses for the production of aluminium profiles. The continuous casting method is a quasi-continuous or continuous process in which strands emerge. These can serve as semi-finished products for further processing or as profiles.

Furnaces

We deal in a wide variety of furnace types for the remelting of non-ferrous metal alloys. Depending on the production process or the machine it involves melting-, holding- and dosing-furnaces, as they are commonly used in the foundry technology. To the respective furnaces, we also offer a wide range of feeding and dosing systems and conveyors for each melt.

Blasting facilities and barrel finishing machines

For surface treatment after forming we offer used blasting facilities and barrel finishing machines. The selection of the suitable machine always depends on the requirements to the surface and the size of the finished parts. The used machines offered by us cover the complete spectrum of deburring and sand removal up to roughen the component surfaces.

Hydraulic and mechanical presses

For the machining of thin-walled metal parts we offer different presses. Hydraulic presses offer the advantage that they can generate very large forces and are versatile therefore. You will also find electric presses here that achieve a very high cycle number and have a cost-effective maintenance. For efficient processing of your metal parts we have different press lines in the range for you as well, which make several cutting and pressing operations when they get set one behind the other. That's how you can ensure that your device is optimally protected against cracking.