Furnaces

The large number of high-quality partnerships, coupled with the professional competence built up within the company, allows us to respond flexibly, holistically and with technically sound solutions to a large number of different customer requirements.

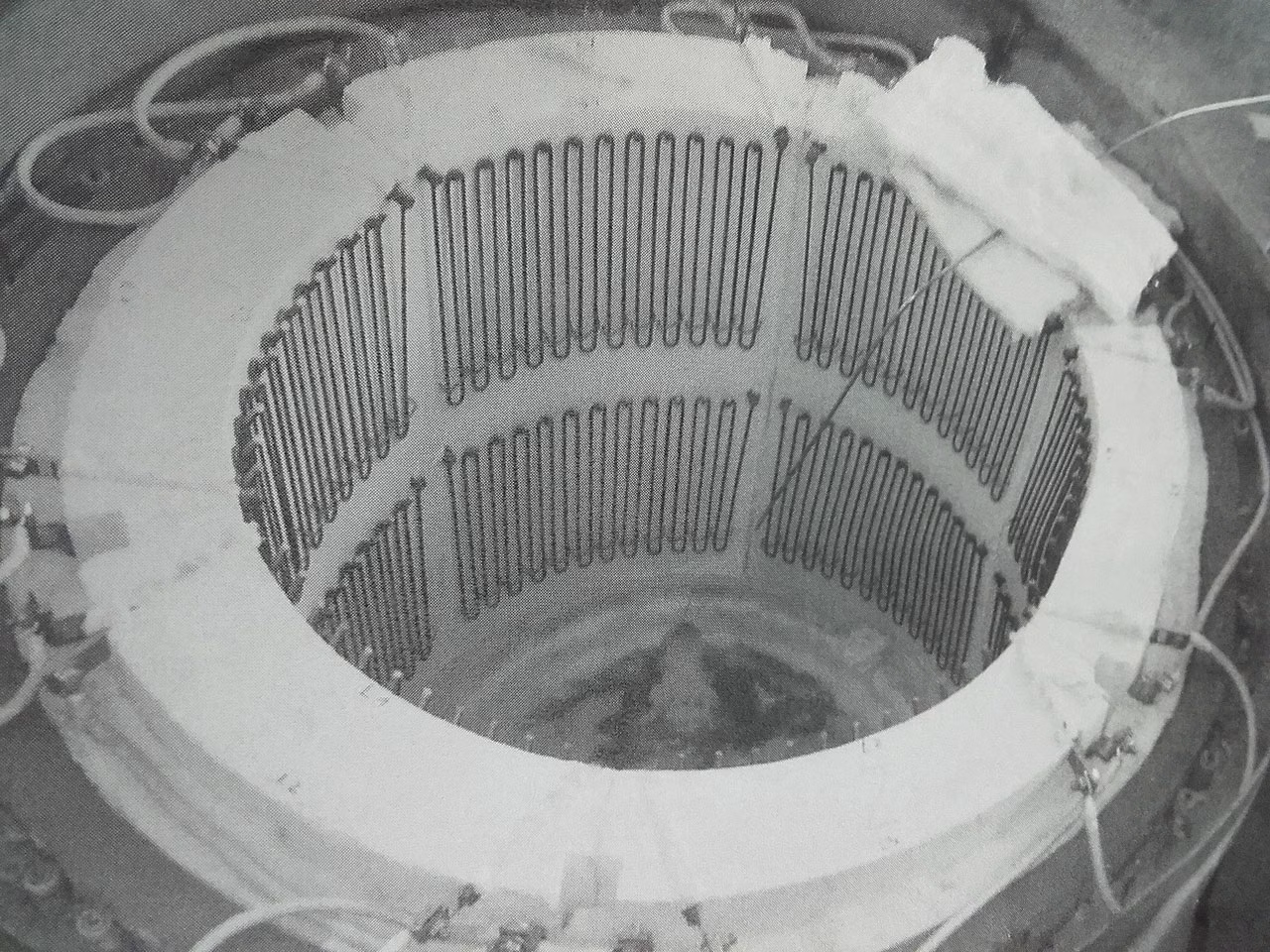

Overhaul of StrikoWestofen WESTOMAT dosing furnaces

Scope of the overhaul work:

- Removal of the refractory lining

- Laying the insulation

- Formwork production

- Welding of anchors

- Door renewal

- Concreting of the floor and walls

- Construction of vaults

- Drilling holes

- Concreting of the insulating coating

- Cleaning of the furnace rim and painting

Overhaul of StrikoWestofen StrikoMelter melting furnaces

Complete lining of the furnaces

- Expert advice on the selection of materials

- removal of old lining manually and mechanically

- Renewal of the furnaces with refractory linings or bricks

- Production of formwork (chimneys and burners)

- Expert advice on the selection of materials

- Monitoring the drying time

renewal of filters, pots and watering troughs

- Expert advice on the selection of materials

- removal of old lining manually and mechanically

- Renewal of the furnaces with refractory linings or bricks

- Production of formwork

- Expert advice on the selection of materials

- Monitoring the drying time - for smaller products, drying is carried out in the workshop (up to 450°C)

Production of refractory products by order

- Watering troughs

- filters, pots

- Wedges, plugs and barriers

- furnace lids and doors

Repairs and maintenance

- casting furnace

- filters, pots

- Wedges, plugs and barriers

- furnace lids and doors

Proven competence and full service

Experienced employees and effective project management accompany all projects from order acceptance to recommissioning. What else can you expect from us? A smooth, personal and transparent cooperation. Everything runs according to plan and you as the customer are regularly informed about the progress of the project!