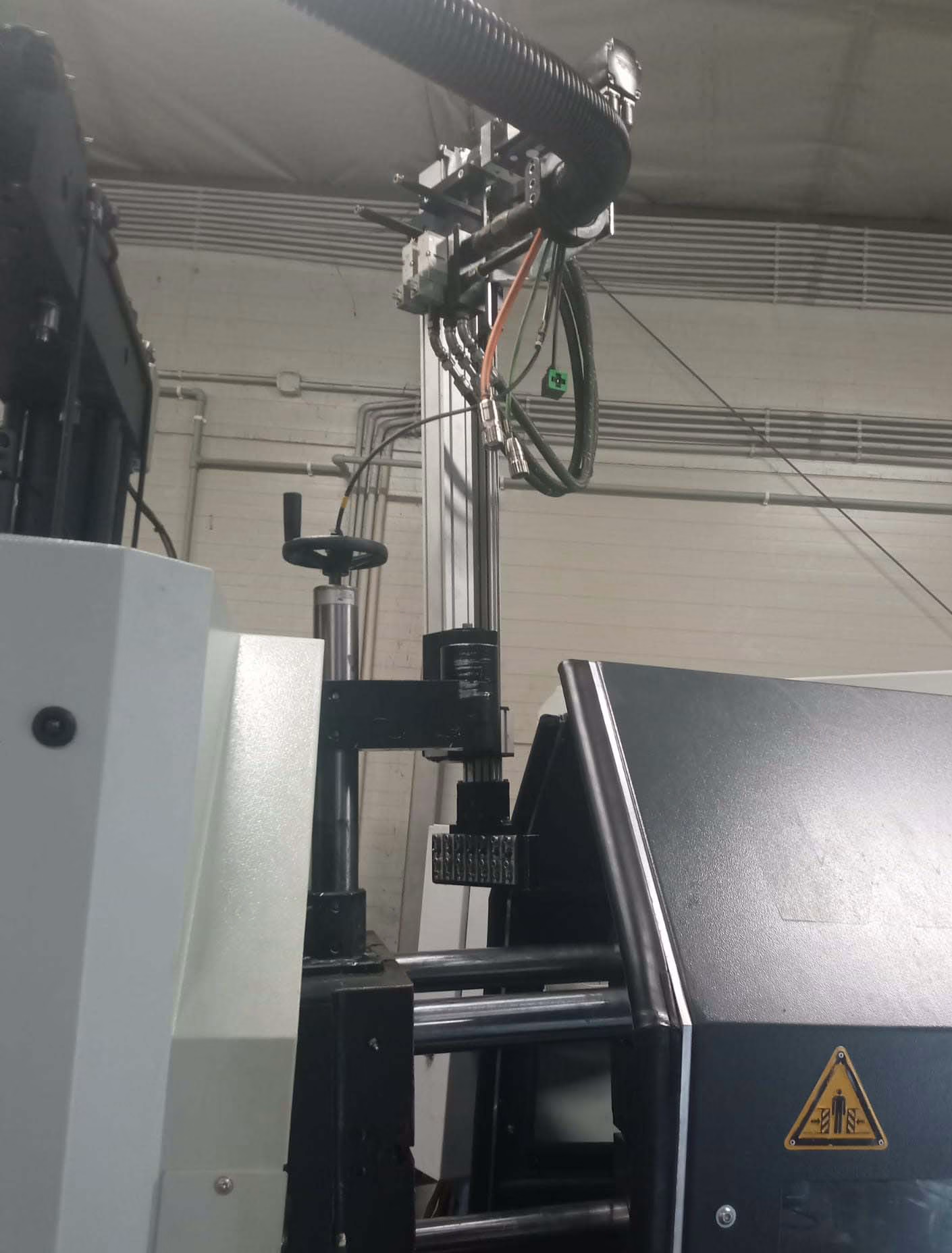

Inspection of a Frech W80 hot chamber die casting machine

We offer a professional inspection of your Frech W80 hot chamber die casting machine to maximise its performance and service life. Our comprehensive services include a detailed inspection and preventive maintenance to ensure your machine continues to operate reliably and deliver the highest quality.

Our services include

- Inspection and maintenance of the hydraulic system: Inspection of the hydraulic pump, valves and hoses for leaks and wear.

- Inspection of the closing unit: inspection and maintenance of the closing unit, replacement of wearing parts such as seals and damping elements.

- Inspection of the meltin and holing furnace: Ensuring correct temperature control and efficiency of the heating elements.

- Inspection of the injection system: Checking the piston, nozzle and injection cylinder for wear or damage.

- Electrical components: Inspection and, if necessary, replacement of controls, sensors and wiring.

- General functional check and fine adjustment: Adjustment and optimisation of the machine for smooth production.

Advantages of inspection :

- Extended service life of the machine

- Less downtime and greater production reliability

- Optimised performance and energy efficiency

- Cost-effective alternative to complete machine replacement

Our experienced technicians ensure that the Frech W80 hot chamber die-casting machine is in perfect condition after the inspection and is once again working with maximum precision.

For further information, prices or a personalised quote, please do not hesitate to contact us. Contact us today to discuss the inspection of your Frech W80 or other type machine!