Professional dismantling, loading and transport of a used Frech GDK 4100-185 S die casting machine to Germany

As part of a challenging logistics project, a used Frech GDK 4100-185 S die casting machine was transported from Korea to Germany. The machine, which is equipped with state-of-the-art automation – including the Wollin PSM 4 F mould spraying machine and the ABB IRB 6700 Foundry Plus robot – has an impressive total weight of 285 tonnes.

On-site dismantling

The dismantling of the large and complex die casting machine was carried out by an experienced team of five skilled workers. Over a period of three weeks, all components were carefully dismantled to ensure safe and efficient transport. Particular attention was paid to the safe handling of the automated equipment in order to avoid damage.

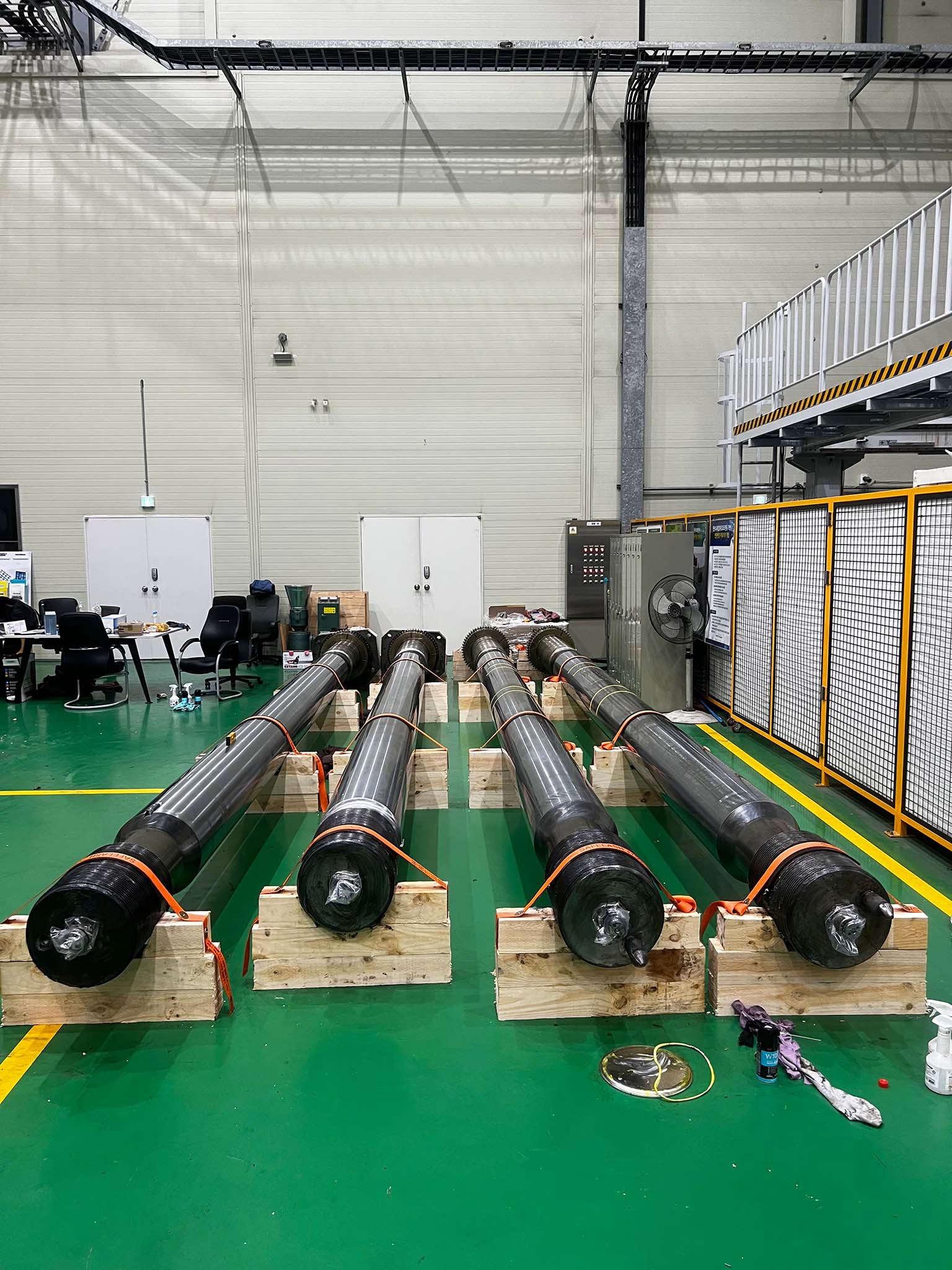

Loading into containers and heavy-duty transporters

After dismantling, the individual machine parts were loaded into special containers and onto heavy-duty transporters. The components were prepared and secured accordingly for safe transport in order to meet the high requirements for heavy-duty transport.

Sea transport to Germany

The machine was transported by sea to Bremerhaven and the Port of Hamburg, two important logistics hubs in Germany. Loading into containers and onto heavy-duty transporters was professionally organised to ensure smooth transfer.

Onward transport in Germany

After arrival in Germany, onward transport of the machine from the port to the customer was organised. Care was taken to ensure timely and safe delivery so that the die-casting machine could be quickly put back into operation.