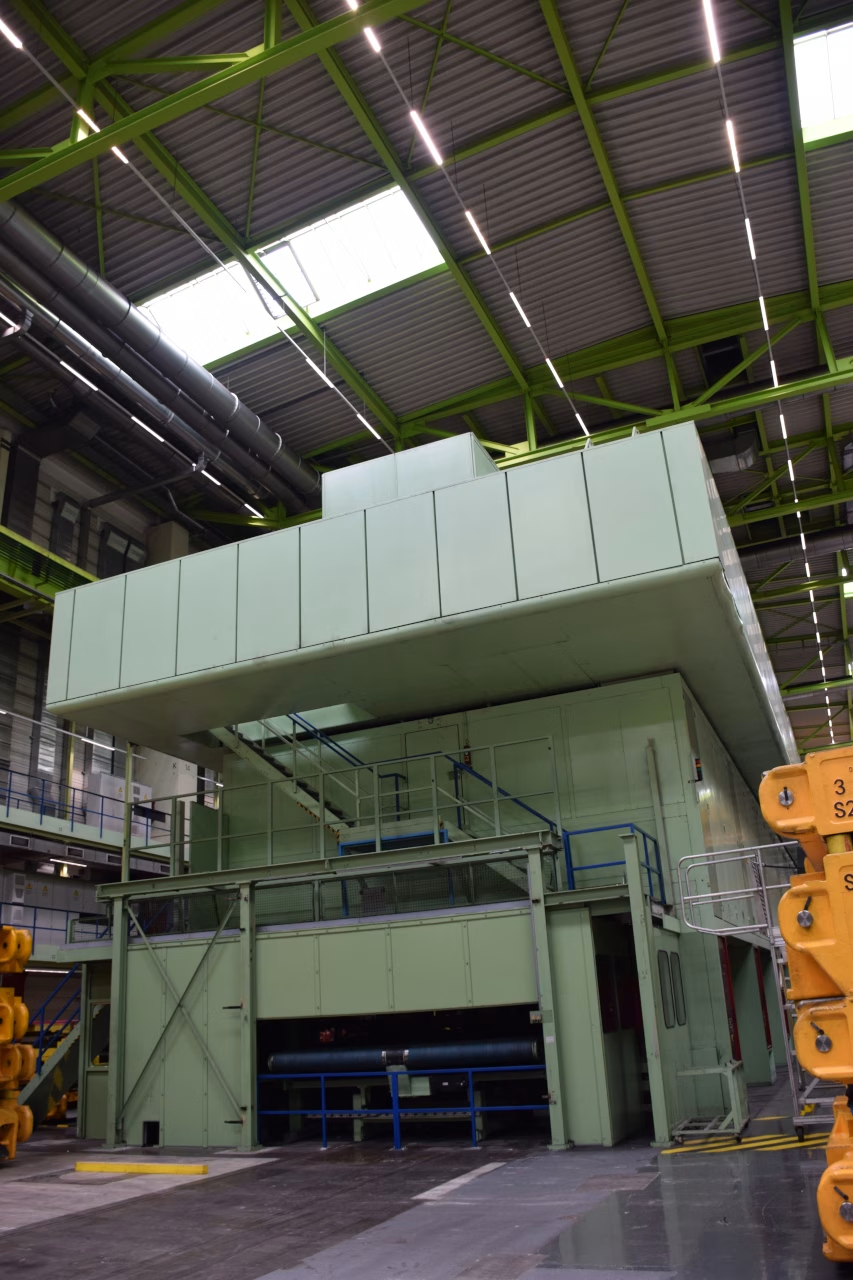

Müller-Weingarten S 7300.06.260 press line PR2494, used for production of Body Panel parts

| Press line | |

| Manufacturer | Müller Weingarten |

| Model | S 7300.06.260 |

| total press force | 73000 kN |

| Year of manufacture | 1994 |

| Operating hours | approx 160.000 hours |

| Control Unit | S7 2012 |

| Comment | For production of Body Panel parts made of steel and partly of aluminum such as: side panels, hoods, fenders and doors. With 15 point drawing cushion |

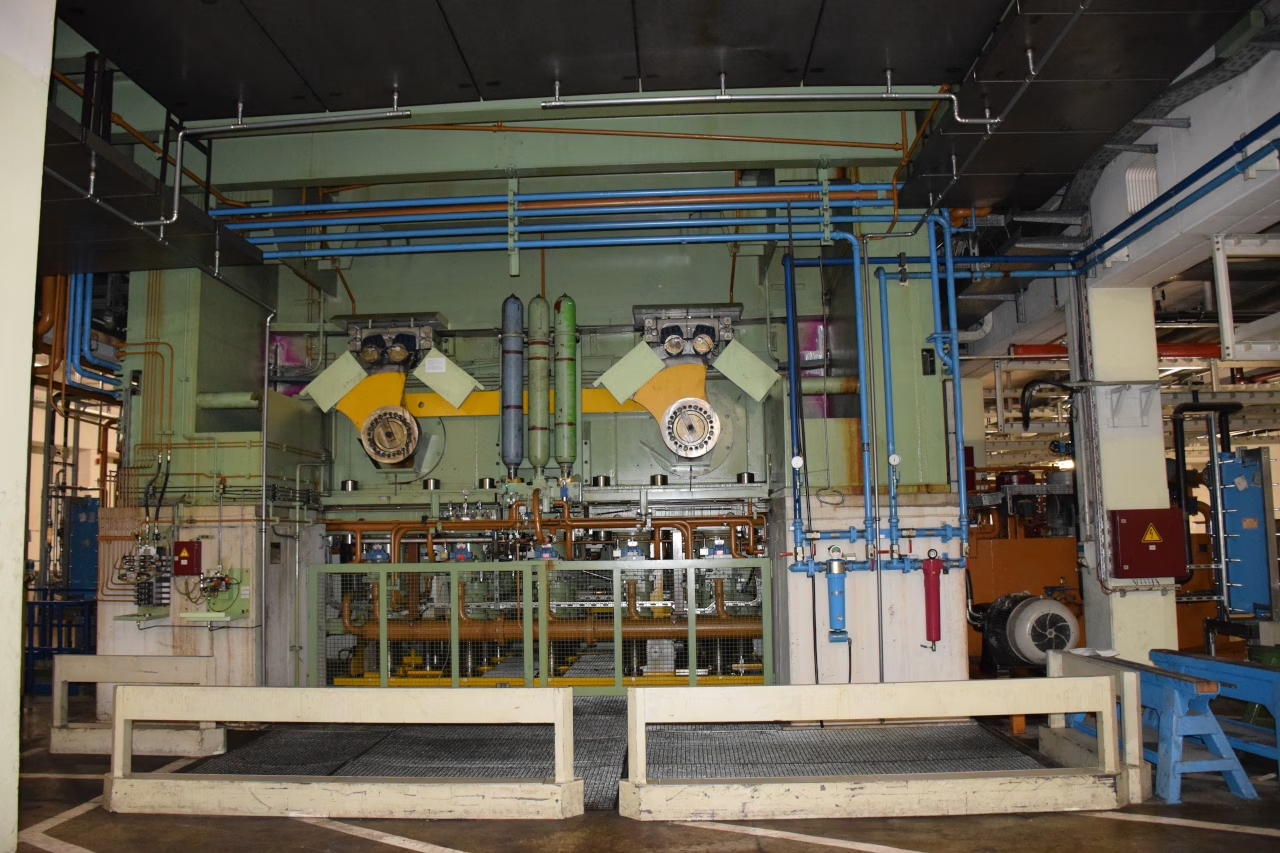

| Technical Data | |

| Pressing force ram 1 | 21.000 kN |

| Pressing force ram 2 | 12.000 kN |

| Pressing force ram 3 | 12.000 kN |

| Pressing force ram 4 | 12.000 kN |

| Pressing force ram 5 | 8.000 kN |

| Pressing force ram 6 | 8.000 kN |

| Working capacity from 6H/min | 2800 kJ |

| Working capacity from 4H/min | 1400 kJ |

| Working stroke rate | 4 -12/min |

| Setup stroke rate | 4/min |

| Installation height between sliding table and ram 1 with stroke down. Adjustment top | 1650 mm |

| Installation height between sliding table and ram 2-6 with stroke down. Adjustment top | 1450 mm |

| Ram stroke | 1560 mm |

| Plunger adjustment | 50 mm |

| Max. Tool weight per stage | 63 000 kg |

| Mold top weight per ram | 38 000 kg |

| Clamping surface sliding table width x depth | 2500 x 5000 mm |

| Clamping surface ram width x depth | 2500 x 5000 mm |

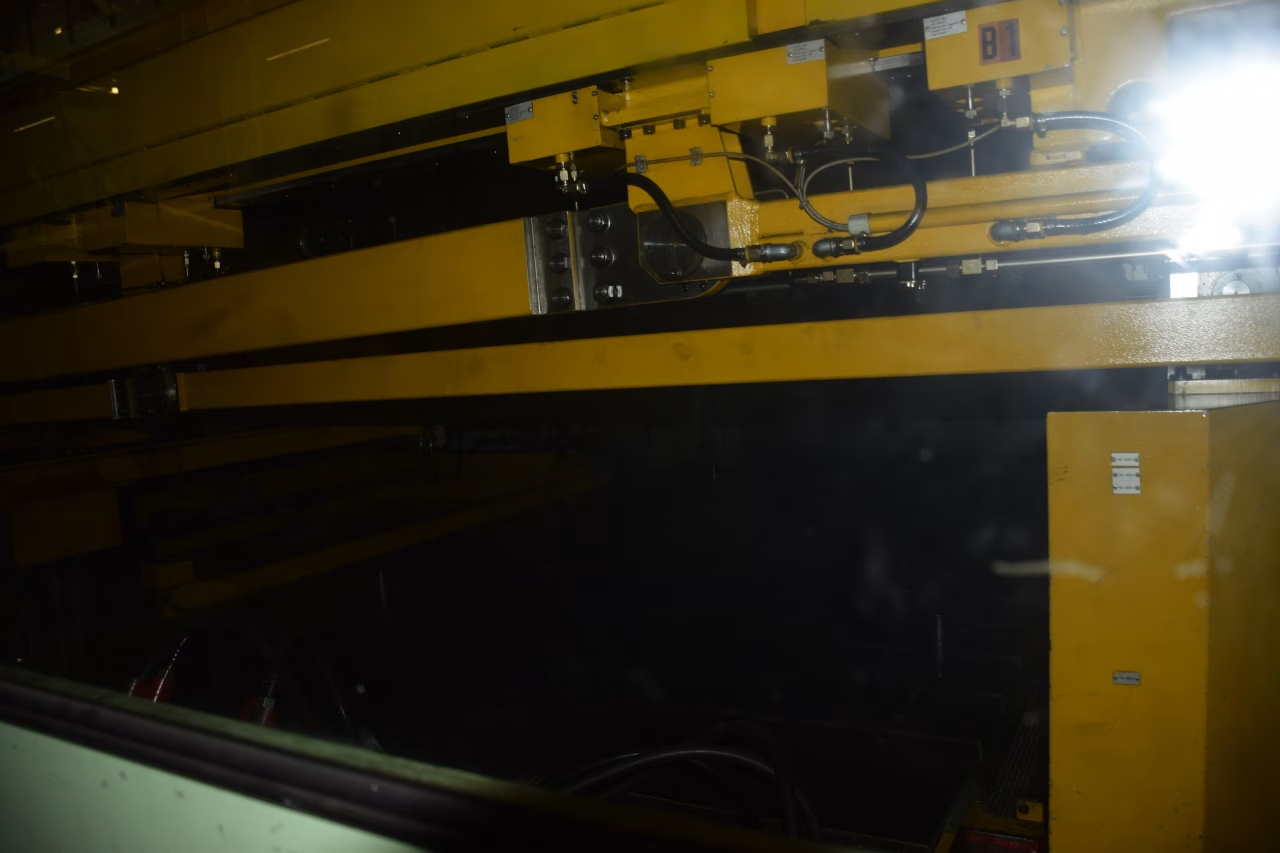

| Hydraulic drawing cushion in table level | 1 |

| Cushion power | 1200 kN - 6000 kN |

| Cushion stroke | 50 - 350 mm |

| Cushion usefull stroke | 0 - 300 mm |

| Air cushion device in ram stage | 2 - 6 |

| Cushion force at 5 bar per ejector stage | 600 kN |

| Cushion stroke | 200 mm |

| Cushion area width x depth | 4300 x 199 mm |

| Distance between the tool steps | 5200 mm |

| Transfer Step | 2600 mm |

| Delivery time | immediately |

| Price | on request |

You are interested in our product? Fill in our offer form and we will get back to you as soon as possible!

You can't come to us? Via videoconference we can give you optimal advice, clarify your technical questions and respond directly to your wishes.

arrange a video conference ›

.JPG)