| Magnesium melting and dosing plant |

|

| Manufacturer |

Rauch |

| Model |

|

| Capacity |

|

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

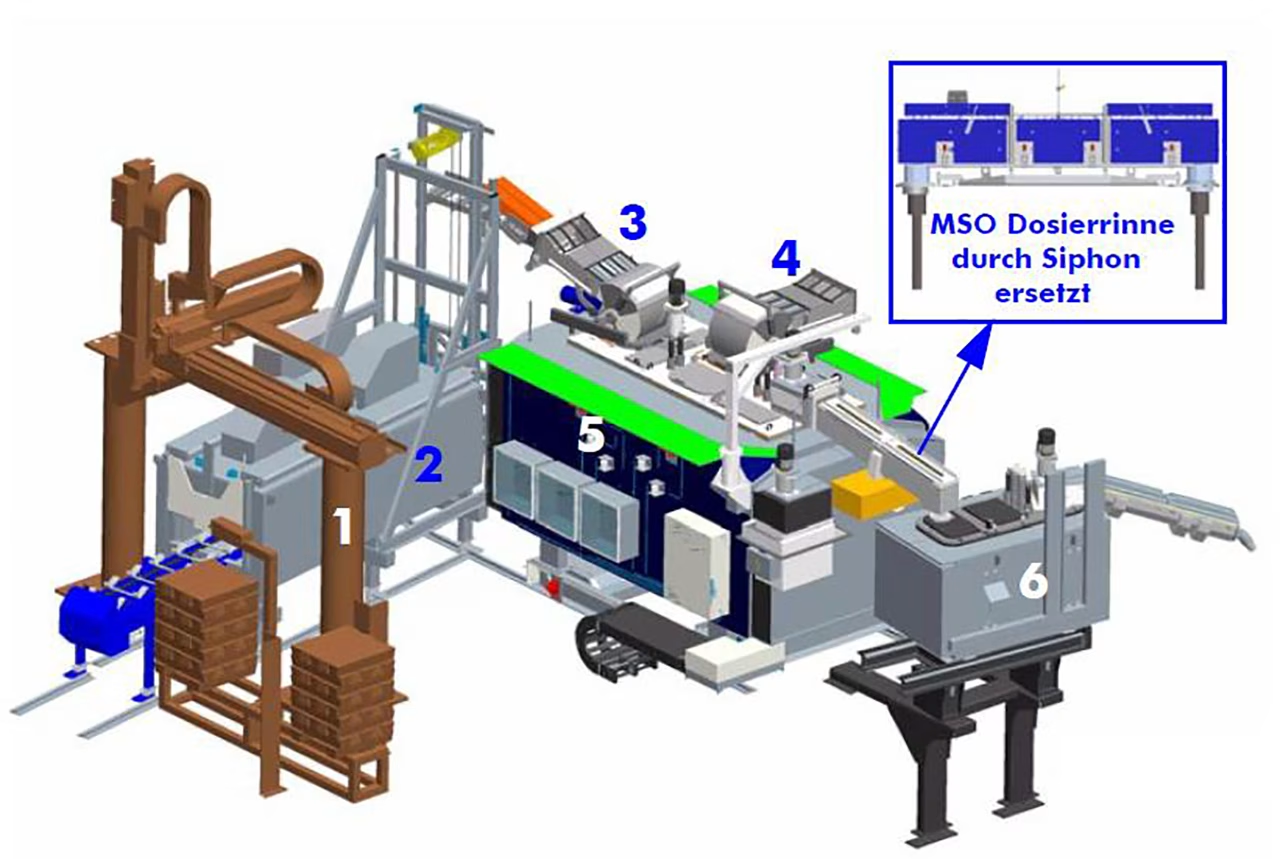

Functional description of the plant

The ingot stack is transported to the working area of the destacking system by means of a chain conveyor.

- Using vacuum technology, the ingot is sucked up at the gripper and transported by means of a gantry to one of the four pick-up points of the MVE supply line and deposited.

- The preheating device and is used to feed and preheat the MDO650E with 8-12kg magnesium ingots.

- The EcoJet XXL system is used for automatic and optimum charging and melting of magnesium ingots and return material.

-The MSO650E is used for melting magnesium ingots and return material.

- The liquid material charged by the MSO is fed via a feed hopper into the crucible, where it mixes with the magnesium present.

- After appropriate release by the die casting machine, the exact dosing quantity is fed to the filling chamber of the die casting machine.

Designation of the plant components

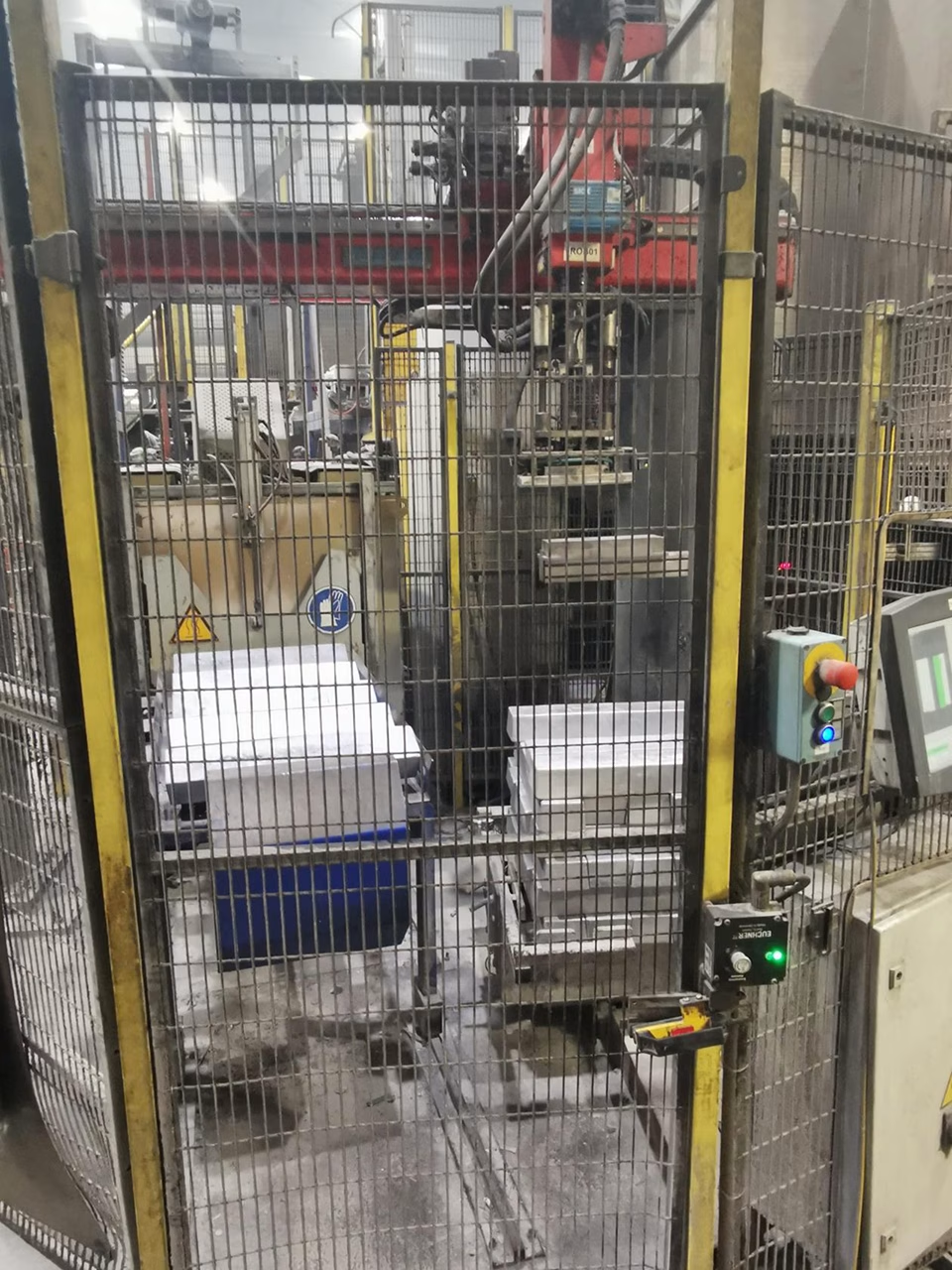

Ingot destacking

|

|

| Manufacturer |

Reis |

| Model |

MRDS

|

| Power |

|

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

Preheating unit

|

|

| Manufacturer |

Rauch |

| Model |

MVE 750E

|

| Power |

65 kW

|

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

Feeding

|

|

| Manufacturer |

|

| Model |

Ecojet XXL ingot

|

| Power |

|

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

Sprue recycling

|

|

| Manufacturer |

|

| Model |

Ecojet XXL sprue

|

| Power |

|

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

Melting furnace

|

|

| Manufacturer |

Rauch |

| Model |

MSO650E |

| Power |

345 kW |

| Melting capacity |

650 kg/h |

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

Dosing furnace

|

|

| Manufacturer |

Rauch |

| Model |

MDO200E

|

| Power |

98 kW

|

| Heating |

electrical |

| Year of Manufacture |

2012 |

| Comments |

|

| Delivery time |

immediatley |

| Price |

on request |