SW BA622 double-spindle machining center BA2353, used

| Machining center | Horizontal |

| Manufacturer | SW |

| Model | BA 622 |

| Year of manufacture | 2018 |

| working hours | 38153h |

Technical data

- Control system: Siemens 840 D SL

- Version with 2 independent Z-axes

Spindle HSK 100 with 375 Nm (2x)

- Motor spindle! In AC asynchronous technology

- with star-delta connection

- Speed range 1 • 10,000 rpm

- Power (25% duty cycle) 30 kW/730 rpm

- Torque (25% duty cycle) 375 Nm

- Rated power 20 kW/730 rpm

- Rated torque 266 Nm

- Start-up time, 1.70 s (n = 0-10,000 rpm)

- Range switchover star - 3000 rpm - delta

- Spindle bearing diameter 100 mm

- Front bearing arrangement 4-fold T-0-T

- Spindle lubrication 01-mlnmal lubrication

- Tool interface hollow shaft OIN69893-HSK-A100

- Tool clamp mechanically operated

- Clamping force > 46 kN

- Media transfer, radial, cleaning air, pan system control

- Media transfer, central, cooling lubricant: emulsion, oil < 80 bar

- Media transfer, central, MMKS: aerosol < 5 bar

Torsion compensation

Hydraulic compensation module for the 4th axis. Used for torsion-sensitive devices and off-centre loads. Compensation torque (adjustable) < 450 Nm Torque constant 1.8 Nm/bar.

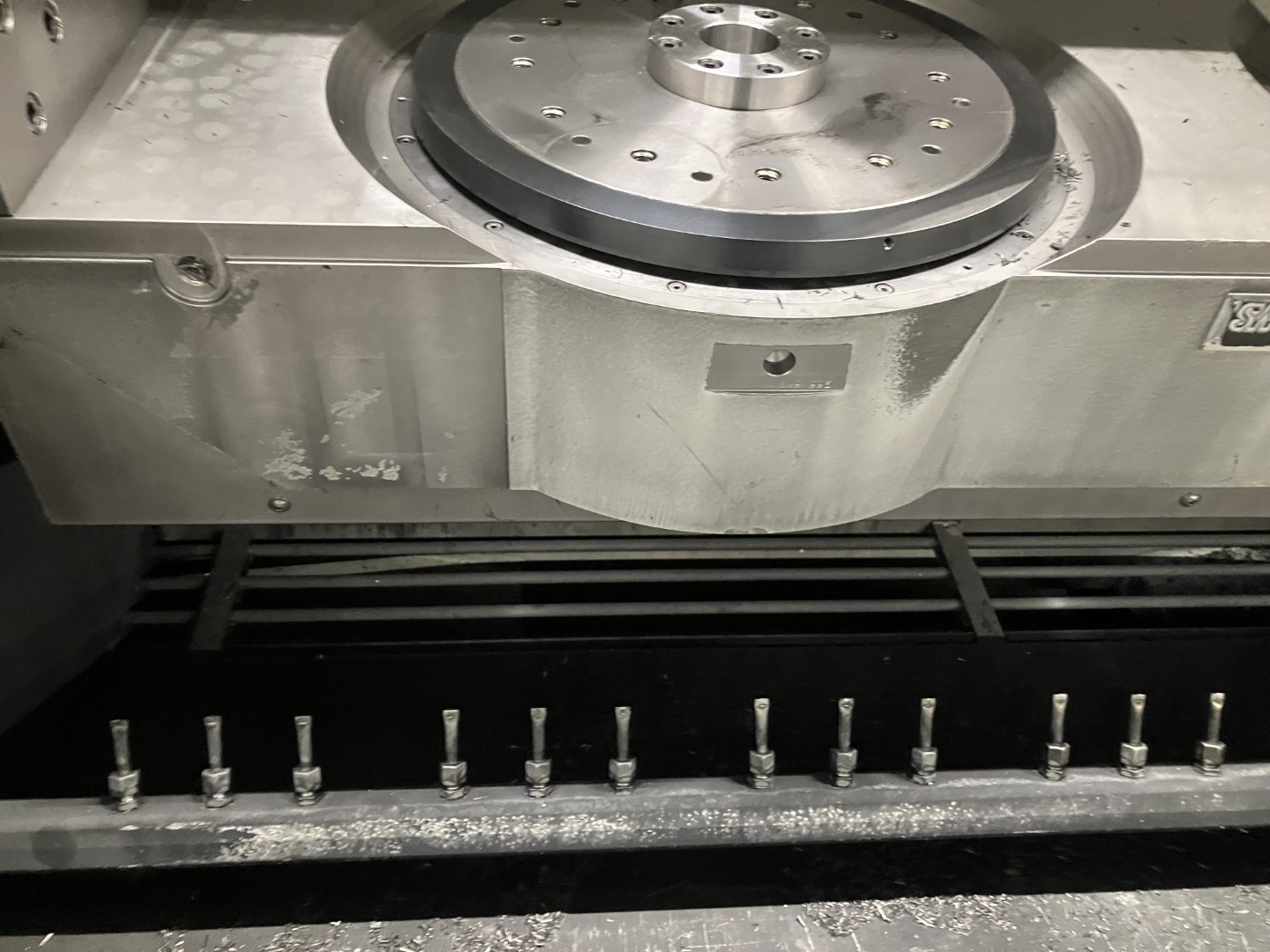

5th axis, 2-fold direct drive

Consisting of:

- 2 direct-drive NC tables

2x 0 340 mm (C1/C2 or W1/IN2 axis) installed in a common crossbeam

- Direct, absolute angle measurement

- Max. fixture dimensions 2x 0 600 x 225 mm (400 mm)

- Max. fixture weight 2x 120 kg

- Peak torque 490 Nm

- Nominal torque 350 Nm

- Max. speed 50 rpm

- Position tolerance without load Tp" 1 r:r

- Tangential torque 2000 Nm Mechanically clamped, hydraulically released

- Weight moment 150 Nm

Rotary distributor

- For working areas 1 and 2 (A, lJ axis)

- Uncontrolled - Leak oil sealed

- Nominal size NG 5

- Distributor track 10

- Max. operating pressure hydraulics 250 bar

- Max. operating pressure pneumatics 8 bar (Connection assignment according to standard assignment plan)

Scraper conveyor (two-part)

(short, broken chips, needle chips, casting chips, casting abrasion, no lumps, no mats)

- Suitable for chips < 100 mm

- Conveyor width 1000 mm

- Discharge height 1100 mm

- Dirty water filter, slotted screen w= 0.35 mm

- Dirty water pump 400 l/min/ 1.5 bar

- Coal dust content approx. 0.3 m

Cooling agent filtration via compact belt filter

Full flow cleaning Top compact paper belt filter for cooling agent emulsion

- Nominal flow rate 400 Vmln

- Nominal filter accuracy 25μm

- tank volume 1.2 m

- Low-pressure pump 200 Vmin at 3 bar

- High-pressure pump, max. 75% EO 40 Vmln at 40 bar

- Heat exchanger for cooling the coal dust via the machine's central cooling system

Pneumatic control, basic module

- Pneumatic control system for advertising stock holders or clamping elements

- Flow measurement - Integrated blow-off function

- 2 probes each for table 1 and 2

- Simultaneous measurement on the loading side of 2 profile controls for table 1 or 2, corresponding to selection - Detectable gap >/= 0.05 mm, corresponding to device design

- Convenient diagnosis and adjustment via SW-HMI

- The determined values are automatically activated by the device selection

Tool breakage detection, inductive

Additional control panel, 19 inches

Tool coding Balluff with chip coding In the tool holder.

PROFIBUS for automation

| Delivery time | immediately |

| Price | on request |